“This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.”

If you do any work on electronics or different hobbies, then you are most likely familiar with soldering. Wave soldering is one of the most popular large-scale processes when it comes to finishing electronics. The question is, what exactly is wave soldering, and how is it beneficial?

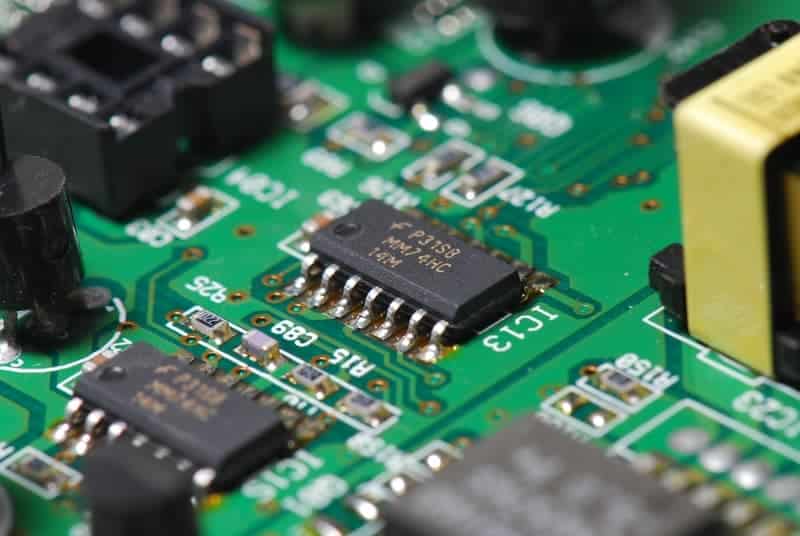

Wave soldering is used in the creation of printed circuit boards. It is often used as a way to create boards in mass quantities in a small amount of time. In addition to being fast, wave soldering is also an effective and stable way to apply components to a printed circuit board.

For those who are looking for soldering processes that are quick and efficient, it is hard to find one better than the wave soldering process. Let’s talk more about what wave soldering is, what it is best for, and complications that you may encounter.

What Exactly is Wave Soldering?

One of the most common forms of bulk soldering is wave soldering. Wave soldering is a quick and effective way to attach different electrical parts to a PCB, a printed circuit board. This is often done with tin alloys.

Here are the four necessary steps of an effective wave soldering process:

- Flux, a chemical cleaning agent, is applied to the bottom side of the PCB.

- The printed circuit board is then preheated before wave soldering.

- The board is passed through a wave or waterfall of molten solder.

- Cool water and air help to cool the board before cleaning excess material.

Wave soldering gets its name from actual molten solder waves being used to attach the parts to the boards. Parts need to virtually travel through the solder to be attached to the board. This process may also look like a waterfall. The solder is held in a tank in order to complete the process.

Wave soldering is used for both surface mounting and through-hole circuit board assemblies. Depending on the method you use, you may need to use some sort of glue or adhesive in order to attach the components before following through with wave soldering.

What are the Steps of Wave Soldering?

As with most soldering processes, wave soldering has a distinct series of steps that make it so easy and quick. While four steps may seem like a long process, wave soldering is one of the quickest soldering processes you can use.

Here is the four-step process of wave soldering.

Fluxing with Chemical Agents

The first step to wave soldering is to make sure you are cleaning your printed circuit board. Fluxing is done by using a chemical cleaning agent on the printed circuit board you are trying to solder. Flexing helps to remove any chemical build-up, oxidation, or even general debris that may be on your board.

There are two types of flux:

- Foam Flux: Best for general areas that need flux applied.

- Spray Flux: Great for small areas or a more controlled spray.

If you are looking for a solid bond between your materials, then this is a step that you cannot skip. It helps to clean any dirt or debris that may be on your printed circuit board. You should also be aware that fluxing can take care of the oxidization of circuit boards as well.

Preheating the Board

On a wave soldering machine, there should be a preheat option. The board is passed through an area with warm air to activate the flux cleaner to clean the board and bring the board to a higher temperature to reduce potential damage.

There are two types of preheating options for most wave soldering machines:

- Infrared: Uses a higher heat that can be random.

- Convection: Has a lower heat but is more even.

If your wave cleaner does not have a heating tunnel or uses an alternate method, make sure you heat your board no less than 65 degrees Celsius and no higher than 120 degrees Celsius. Preheating also helps to ensure proper attachment for any electronic component that you are adhering to your PCB.

The Wave Soldering Process Itself

In this step, it is time actually to apply the solder to the circuit board. On wave soldering machines, the solder is actually a paste until it begins to heat up. Once it heats up, it acts as a wave or waterfall that the circuit board will pass under.

With most wave soldering machines, there are two types of wave patterns:

- Laminar Waves: Waves are smooth and have an appearance similar to a waterfall. These are the most popular type of wave pattern.

- Turbulent Waves: A high-pressure wave is mostly used for through-hole wave soldering. It is also used for dense materials and can help remove excess solder.

The solder used in wave soldering is often a combination of lead, tin, and antimony. For a lead-free alternative, more and more production facilities are using tin-silver-copper or tin-copper-nickel alloy blends.

Cooling the Board Back Down

Although cooling is the final step in the wave soldering process, it is still essential. Allowing your circuit board to cool slowly can ensure that your components are properly sealed and that your board is in excellent condition. Forcing your board to cool too quickly can result in damage. Even too slowly can be a recipe for disaster.

The ideal way to cool your freshly soldered circuit board is by using a spray bottle with cool water or cool air. You want to cool your circuit board at a steady rate, and using these methods will allow you to control the cooling process.

What are the Important Factors of Wave Soldering?

Now that you know the necessary process of wave soldering, there are a few factors that can help ensure that your circuit boards come out perfectly. Any of these can result in an error in your product if they are not adjusted to your current project.

Here are three factors that you need to be aware of.

Temperature is Crucial in Wave Soldering

The single most crucial factor with wave soldering is temperature. Depending on the type of materials you are using, there are two temperatures that you need to remember. The first temperature is 280 degrees Celsius, which is the ideal temperature for heavier materials—the second is 230 degrees Celsius for lighter materials.

Temperature is also important to ensure that the flux method you used has been activated. If not, then your solder will not be able to adhere to the circuit board, and you can run into components, not bonding, or other severe issues that can ruin the board altogether.

The Height of the Solder Wave

Even the height of your solder wave is essential to getting the perfect result. When your board passes under the wave, the solder’s ideal amount of time should come in contact with your board is anywhere from two to four seconds.

Depending on the wave solder machine you are working with, three settings can control these:

- Conveyor Speed

- Wave Height

- Pump Speed

If you find that you are having contact issues, try using a random item to help understand what adjustments need to be made without ruining any materials or boards. Most of the time, people prefer to use tempered glass to help make these adjustments.

How to Increase the Effectiveness of Your Wave Soldering Process

When it comes to perfecting your soldering process, there are a few factors that you need to take into consideration. These are vital parts of the wave soldering process as a whole, but let’s examine them further.

The three ways to increase the effectiveness of your wave solder result are:

- Even application of flux

- Proper heating

- Know your solder

Flux is the first step in the wave soldering process, and it plays a crucial role in how your circuit board will turn out. You know what the purpose of flex is, but knowing how to control flex is essential. How evenly flux is applied, and the flux density you are using can make a difference in your results.

Heating is another area where many creators can go wrong. Failing to heat your board or to overheat your board can cause issues with flux activation. In some cases, you may even end up burning off your flux or damaging your board beyond repair. Heating can be controlled on your machine and is something that you should adjust to your liking.

Lastly, the solder you are using and how you treat it are crucial factors. Most of the time, your machine will monitor your solder’s temperature, but there are additional tools that you can use to make sure it is at a working temperature. The solder’s contact time with your board and how fast it comes out are also important variables.

How Expensive is Wave Soldering?

For many people, the cost is one of the key factors they are interested in. Considering that wave soldering is done with a large multi-step machine, it is going to be more of an investment than a hobby solder iron.

There are five aspects you need to consider with estimating the cost of wave soldering:

- Upfront machine cost

- Solder fee

- Flux cost

- Maintenance

- Electricity

Considering that your standard wave soldering machine can cost anywhere from $10,000 to $20,000, it is a significant cost to absorb, especially if you are starting out. Most wave soldering machines belong to companies that operate in bulk processing to ensure that the machine’s cost is worth it.

A less obvious aspect that you should take into consideration if you are thinking of purchasing a wave soldering machine is the labor. Is it going to cost less for you to create bulk printed circuit boards than it would to solder them by hand? If so, then a wave soldering machine may be a wise decision.

How Much Does Flux Cost?

Flux is one of the main components of a wave soldering machine. Not only does it help the solder attach to the board, but it also helps to keep your product in the best shape possible while it is being made. Flex is one of the additional costs you need to consider when purchasing a wave soldering machine.

Factors that impact the cost of your flux:

- What kind of soldering you are doing, commercial or personal.

- The kind of machine you have chosen and what is compatible.

- The formulation of your flux.

It is hard to estimate what flux will cost without knowing what you are going to choose. On average, you can expect to spend anywhere from $2,000 depending on what you choose and how often you are using your wave soldering machine. If you are unsure what to choose, contact the creator of your machine for their recommendations.

How Much Does Solder Cost?

Solder is going to be one of the higher costs for your wave soldering machine, as you may expect. Most of the time, the solder you will purchase for your machine can cost you as much as the machine itself. It comes in either a solid form that melts down in the machine or a paste form with some methods.

Solder costs can run over $25,000 for one year of regular use, and nitrogen and electrical costs can also end up being over $20,000. With a potential yearly usage cost of $50,000, you need to be producing a lot of circuit boards to make any sort of return on your investment.

If you use selective wave soldering, then you will actually be using a solder paste. Solder paste not only includes the solder that you will need for your project, but it also contains flux. This is an excellent method for those who are looking to get similar results without spending a fortune.

What Can Go Wrong with Wave Soldering?

Even though wave soldering is pretty straightforward and straightforward to grasp, there are still things that can go wrong. Many of the potential errors you can make in wave soldering have to do with temperature, speed, and even your board or machine design. Here are some of the most common wave soldering mistakes.

Bridging Between Components

One of the most common problems you can encounter with wave soldering is where the wave actually connects different components. While this may not be a big deal in some cases, with soldering can actually create an unwanted connection.

Here are some causes of bridging:

- One or more of your settings is off.

- There is not enough flux, or it could have been burnt off.

- Your board was not preheated long enough.

To reduce bridging, place masks in the area between your connections. This will help create a boundary and cut down on the solder continuing over. You can also use a hand solder iron to melt away excess solder. If this continues to be a problem, it may be worth making adjustments to your machine.

Insufficient Solder for Joints

If you do not make the necessary changes on your machine when you notice a mistake happening, then you may run into insufficient solder. You may not have enough solder to cover the board you are working on or an issue with your flux.

Here are the main reasons why you may experience inefficient solder.

- Conveyor speed is too slow.

- Solder temperature was too low or has begun cooling.

- The wave height was too low.

Prior to beginning your wave soldering process, you may want to check your solder levels. Especially if you have not checked them in a while or you have been soldering more than usual. It would be best if you also did regular checks on different parts of your machine to ensure nozzles are clear and everything is working correctly.

Solder Balls and Spattering

While you are soldering, you may notice that your solder is actually balling up. They may also attach to different areas of your board and can lead to different issues such as build-up, bridges, or even ruining your board completely.

Here are a couple of things to look at if you deal with solder balls often:

- Speed is too slow or fast.

- You have applied too much flux.

- The board temperature is not high enough.

For most people, flux is the biggest issue that causes solder balls. Make sure your flux is reactive as well as applying evenly prior to the heating process. If this becomes a recurring problem, you may want to check your board’s internal temperature right before it heads into the wave soldering area of the machine.

Components Moving Around While Soldering

This is most common when you use surface mounting, but it can haven with through-hole as well if you do not secure the different components onto your circuit board with some sort of adhesive prior to wave soldering.

Here are some additional reasons why your components may move during wave soldering:

- The speed of your wave solder may be too fast.

- Your board may be exposed to the solder too long.

- There is an issue with your lead length.

The best way to ensure that your components are staying put during the wave soldering process is to make sure that your board is clean before flux is applied. This creates a better surface for connection. You should also use some sort of solder-friendly adhesive to help your components stay put at all stages of this process.

Solder Flooding the Board

Flooding is possible with wave soldering is that you may accidentally flood your board. This happens when you apply too much product to an area that you are working on, and it is extremely easy to do if you’re using the selective wave method.

Here are some additional reasons why you may experience flooding:

- Board may be warped or damaged in some way.

- Your wave height may be too high.

- There may be an issue in the settings of your conveyor.

Flooding is easy to do with wave soldering, especially if you do not have the settings on your machine right. While in some instances it may be okay, looking to do selective or partial wave soldering can be ruined if your nozzle applies too much solder or if your board is warped or unbalanced on the conveyer.

Solder Skips an Entire Section of Board

Although it doesn’t happen all of the time, solder skipping is not only frustrating, but it can be a sign of a bigger problem in your wave soldering machine. Solder skipping occurs when one part of your board either is missed or basically skipped over.

Here are the most common reasons why you may have solder skipping:

- Your conveyor speed is too fast.

- Not enough flux was applied, or it was not applied correctly.

- Wave height is too low.

You should always be checking all connection points after your circuit board comes out of the wave soldering machine. Not only is it necessary to make sure that your boards operate correctly, but it can cause you more work down the line. Make sure to keep a record of proper settings and always compare them prior to soldering.

Is it Possible to Create your Own Wave Solder Machine?

With the extreme cost of wave soldering, many hobby creators tend to wonder if they can create their own type of wave solder machine at home. Wave soldering is primarily a bulk soldering process that is used to create multiple circuit boards at home.

Some people have created successful at-home wave soldering machines using frying pans and even toaster ovens. The truth is that because these methods worked for someone, it does not mean they are safe to do in your own home. You also will have to buy flux and solder still.

The best option if you are looking for a small-scale wave soldering option is to either use a selective wave method or to do a more traditional soldering method. Although it may take more time than you want, it is going to save you effort and money in the long run.

Are There Different Soldering Processes That Are Similar to Wave Soldering?

When you look into wave soldering, you may also see a lot of information about reflow soldering. While wave soldering is a popular method for working on printed circuit boards, there are also a few methods that wave soldering becomes confused with.

A couple of processes similar to wave soldering include:

- Reflow Soldering

- Selective Soldering

Reflow Soldering: Wave Solder without Flux

Reflow soldering is quite similar to wave soldering except that it does not use any flux. It is primarily used in the surface mounting aspect of soldering. Reflow soldering is also performed in a different machine than wave soldering, which means you need additional equipment.

Reflow soldering also has a four-step process:

- Preheating

- Thermal Soak

- Reflow Soldering

- Cooling Period

Reflow soldering sometimes combines the solder and flux into one paste that is applied to the circuit board. The components are attached to the board using the solder paste to adhere to the electrical components temporarily.

Reflow soldering is often used to reduce waste materials if you are working on smaller projects or select areas. Since you are not entirely covering the board with the solder, there is also less chance for common issues that arise with wave soldering. That being said, there are still specific issues with reflow soldering.

- Using old paste can cause your parts not to adhere.

- Left unused, your flux may separate.

Selective Wave Soldering: Partial Wave Soldering

Depending on what project you are working on, you may not be able to do a complete wave solder. This is where selective wave soldering comes in. It is ideal if you want the same outcome as a regular wave solder but only in certain areas.

There are four critical differences with selective wave soldering:

- Flux has to be applied by hand.

- The circuit board needs to be assembled prior to soldering.

- Preheating has to be done by hand outside of the machine.

- A site-specific nozzle is used as opposed to the traditional wave.

One of the main benefits of selective wave soldering is that it costs less than traditional wave soldering. Not only are the machines smaller, but they also require fewer materials overall. You also cut down on cleaning and the potential for things to go wrong. With that being said, there is still plenty that can hurt your circuit boards.

- High temperatures can dissolve padding.

- Balls can form if the copper polymer gets too hot.

- You may create extra connection points due to excess solder.

- Excess solder may fall on different areas during soldering.

Final Thoughts

For those working on bulk printed circuit boards, wave soldering is genuinely the best option to maximize outcomes and keeping costs as low as they can be. Wave soldering uses four different steps to create the wave soldering process.

The four steps of wave soldering are:

- Flux Application

- Preheating

- Solder Application

- Air or Water Cooling

Wave soldering uses a combination of flux, heat, and solder to help combine electrical components through both surface mounting as well as through-hole mounting. The entire wave soldering process is done through a machine that cuts down on mess but has a massive increase in terms of space used.

Unless you are working with bulk products, wave soldering may not be the best option for you. Selective soldering and reflow soldering can help you can get similar effects without the extra costs and large materials.

Sources:

What is Wave Soldering? | Bittele Electronics Inc. (7pcb.com)

Selective Solder vs Wave Solder | Bittele Electronics Inc. (7pcb.com)

Wave Soldering | OurPCB Tech (ourpcb.com)

Comparison Between Wave Soldering and Reflow Soldering | Tech Briefs Media Group (techbriefs.com)

Wave Soldering | Wikipedia (en.wikipedia.org)

SMT Quick-Tips: Selecting a Wave Soldering System | DDM Novastar Inc. (ddmnovastar.com)

Wave Solder Machines | PCB Unlimited (pcbunlimited.com)

Hand Solder vs. Wave Solder | Circuitnet Media LLC. (circuitnet.com)

What Are Reflow Soldering & Wave Soldering? | PS Electronics (quick-pcba.com)

Simple, Effective Process Control in Wave Soldering | SMTnet (smtnet.com)