“This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.”

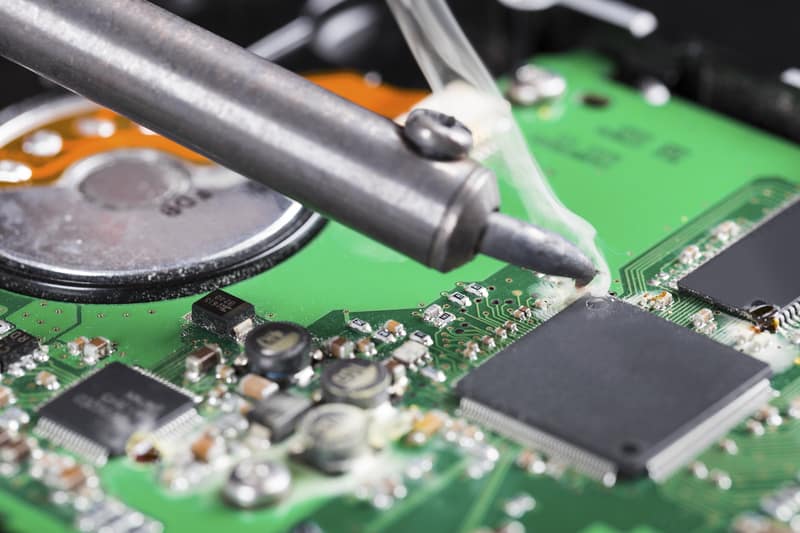

Soldering involves heating metal at a high temperature and requires precision at every turn, meaning proper maintenance is a must. Most importantly is the maintenance of the soldering iron tip, a crucial step in retaining optimal performance, cleanliness, and safety.

Soldering iron tips wear out over time due to the construction of the tool. To maintain a properly working soldering iron tip, there are many steps you need to take. Today, the goal is to explain the most important steps in maintaining a soldering iron tip and what to do when problems arise.

Maintaining a Soldering Iron Tip

Maintaining a soldering iron starts with the tip, which is the most delicate part. It is also the most important part, allowing you to work with precision and safety. Therefore, ensuring proper maintenance is imperative to keep the tip in good shape. However, maintaining a soldering iron tip is not a one-step job and takes constant effort.

To maintain your soldering iron tip, you need to consider things such as how to store it, what steps to take to do as little damage during use as possible, and how to fix any damage that might have been done.

Ensure Proper Storage

Before you begin thinking about the different steps to take to actively maintain your soldering iron tips, you must make sure you follow the correct storage techniques. First off, your soldering iron storage must be clean and sealed to prevent oxidation of the tips, which can ruin them, even if they are not in use.

An important thing to note before putting your tips away is that you must clean and tin the tips every single time. Tinning your tip is mainly used if you are storing your tips for an extended period, but following this rule at all times will extend the life of your tips and further prevent oxidation. Remember to ensure that your tip is cool prior to storing it.

If you are storing a tip for a brief period, such as when switching components or switching between joints, store it in a secure soldering iron holder. You can keep the tip at an idle temperature so that it can be used again quickly. However, do not store it at its operating temperature because that will reduce the lifespan of the soldering iron tip.

You can also loosen the screw that holds it into place before storing it, which will prevent a potential issue with the tip becoming stuck, known as seizing. Regardless, correctly storing your soldering iron tips is an important step that you can take to make sure they have a long lifespan and need as little active maintenance as possible.

Clean the Tip

Cleaning your soldering iron tips is another crucial step to ensure that they continue operating properly and for extending their lifespan. In fact, soldering iron tips should be cleaned before, during, and after use. Fortunately, there are several useful methods to maintain the cleanliness and effectiveness of your soldering iron tips.

- You can use a damp sponge. Using a damp sponge simplifies oxide removal, but if it is not damp enough, it can catch fire, so pay attention. Also, a damp sponge can result in a thermal shock to the tip by rapidly reducing the heat, and the rapid change in temperature can be bad for the lifespan of a tip.

- A Dry Cleaner is a system made of metal shavings that are coated with flux. Thrusting your soldering iron tip into a Dry Cleaner several times will quickly and properly clean it. Also, when you avoid the thermal shock that comes from a wet sponge, you are preventing the tip from rapidly expanding or shrinking.

- Metal wool is another common and effective tool used to clean soldering iron tips. It will remove dirt and contaminants without introducing thermal shock. Be sure not to use anything more abrasive, such as sandpaper, because that will also reduce the lifespan of your soldering iron tip drastically.

Solder Quality Is Important

Low-quality solder contains many contaminants which, if used during soldering, will build on the tip and reduce the lifespan and effectiveness. While this may take a while, it is a surefire way to ruin a soldering iron tip. Instead, use a high-quality solder from a reliable vendor, which will increase the effectiveness and lifespan of your tip.

It is a good idea to test the quality of your solder before using it. One way to do this is to heat it up and see how easily it melts. Quality 60/40 tin/lead solder will melt at around 460 degrees Fahrenheit, whereas low-quality solder may not melt entirely or very quickly. It is a quick test, but it can tell you a lot about the quality of the solder.

Make sure that you check the manufacturer’s instructions for your solder before use. This is an important step because each solder has a different melting point, which will impact the quality test. It is also useful for adjusting the soldering iron temperature, which you want to sit just above the melting point to prevent oxidation due to heat.

Another way to determine the quality of your solder is by identifying the levels of lead and observing their appearances after use. Melted lead solder should appear shiny. If it appears matte, it is not of great quality. However, lead-free solder should appear matte if it is of high quality. Remember, the higher the quality, the better it is for your tip.

Maintaining the Correct Temperature

If your solder tip is not operating at peak performance, be careful not to fall into the trap of increasing the temperature more than needed. It will turn into a perpetual cycle of decreasing the lifespan and effectiveness of the tip, requiring you to turn up the temperature even further.

Using a soldering station that has a temperature sensor is a great method for making sure you are using the correct temperature. These stations allow you to set your temperature to an idle state in between use, further increasing the lifespan of your tip.

Each type of solder should come with a set of instructions from the manufacturer. Be sure to review these so that you are setting the temperature correctly. Not following the instructions will result in poor performance and degradation of your tip quality, potentially even leading to oxidation.

For advanced users, there are soldering stations that use microchip processors. These processors will maintain the correct temperature with minimal fluctuations. This will protect you from sudden temperature increases and thus avoid oxidation on your soldering iron tip.

The Role and Dangers of Flux

When molten metals come into contact with oxygen, they form an oxidation layer. Flux serves to eliminate the oxidation layer by dissolving it, which is achieved when the flux is melted with the solder. Using the proper type of flux will allow for optimal performance of your soldering iron tip and prevent the risk of oxidation, which helps maintain the tip.

It is important to note that you should avoid using flux to clean your tips. The reason is that flux is corrosive. Certain types of flux also carry risks that impact the tips. A few types of flux that can damage a tip are:

- Water-Soluble Flux: Water-soluble flux is known to damage tips at high temperatures. If a project requires water-soluble flux, do a full cleaning after use, though using it will still reduce the lifespan of a tip.

- No-Clean Flux: No-clean flux is another alternative flux that is used for soldering parts that require little or no cleaning. While it can be useful in certain situations, it is not enough to remove oxidation from a soldering iron tip. As mentioned, an oxidized tip is bad and will hurt its lifespan.

Tinning the Tip

Tinning the tip is a crucial step to improve its lifespan and effectiveness. Your soldering iron tip should be tinned at all times, including before, during, and after usage. A good rule of thumb is to tin your tip every two to three joints to protect it from oxidation. Following this step will also make sure heat is flowing to the tip efficiently.

A properly tinned soldering iron tip will allow for more optimal heat transfer between the tip, solder, and the material you are soldering. If heat transfer is optimal, you will not have to worry about readjusting the temperature, which would erode your soldering iron tip over time if done incorrectly.

To properly tin your tip, make sure it is clean and free of any oxide layers. Then, apply a small amount of solder to the tip. After the tip has been tinned, it is best to begin soldering right away to ensure tip health. If you have concluded your work, tin the tip, turn off the soldering iron, and put it in your storage container.

When tinning your tip, it is also a good time to make sure the tip is installed and seated correctly to your soldering iron. If it is not fully fastened, the tip may not be receiving enough heat. As a result, the effectiveness will be reduced and thus the lifespan of the tip will be reduced.

Stress and Cracking

While maintaining a tip is important, there are certain types of damage that cannot be fully prevented with care and regular maintenance. One such type of damage is cracking, which mainly results from stress.

The tip of a soldering iron is made out of, well, iron. Unfortunately, while iron has many positive properties, it is not great at resisting fractures, meaning excessive pressure will cause cracking in the frame. When a crack occurs, the copper located inside the tip will melt, soon leaving the tip hollow and useless.

The largest causes of cracking are improper use and accidents. To prevent cracking, keep these precautions in mind:

- Use the largest tip you can for a specific job. Larger tips mean more iron, which means less chance of cracking.

- Be careful. Do not apply excessive pressure or strike the tip against anything hard since it could crack.

- Only use the tip for its purpose, not as a lifting tool or anything else.

The takeaway is that tips are not that strong, even if they are made out of metal. Use them properly, and be careful with them to properly maintain your soldering iron tips, especially the smaller precision tips.

Corrosion

Another problem that crops up is corrosion. One source of corrosion was mentioned previously, flux. However, with proper cleaning, flux poses few real problems and is almost always used when soldering. There are also non-corrosive fluxes, such as RMA flux. Consider these suggestions to prevent corrosion:

- Use lower activity flux when you can, such as RMA flux for the longest tip life.

- Use a non-corrosive solder, such as an RMA-containing solder, when tinning for storage.

- Use sponges that do not contain sulfur, and ensure that your sponge is clean.

Remember what you have wiped off using a sponge, and ensure that you always use a clean one. By keeping both flux and sponges in mind, you can decrease the chances of corroding your soldering iron tips.

Wear and Tear

While the wear of a tip seems like an obvious problem, there are many things that can negatively impact the life of your soldering iron tip. Some have already been mentioned, such as using the largest tip possible, which protects it from cracking but also takes advantage of the extra plating to last longer.

Another thing is to never scrub the soldering iron tip. While not using rough materials has already been mentioned, remember that most soldering iron tips are delicate, able to be scratched, cracked, or harmed in various ways with the slightest slipup. You may not directly break the tip, but any damage done will last and have an impact.

Dragging the tip of your soldering iron to spread solder is not only bad practice, but it will also impact the life of the tip. As mentioned, the tips are delicate, so anything rough will have an impact. Considering that dragging will quickly remove the protective layer makes it particularly harmful.

Reactivating a Solder Tip

If your soldering iron tip gets damaged, it may not be completely lost. If it is not completely finished, it is possible to reactivate it. You should take this step when your tip is not defective but has a thick enough layer of oxide on it to require abrasive chemicals to remove.

Follow these steps to attempt to reactivate an oxidized tip:

- Place the tip into an activator and move it around

- Once it becomes shiny, remove it from the activator and clean off any residue

- Immediately follow this up by tinning the tip

Reactivated tips might not be as sturdy, so make sure you take extra care of the tip during use, tinning it often and using it with care.

Replacing a Solder Tip

All good things come to an end, and eventually, you will have to replace your solder tip regardless of how meticulously you care for your equipment. Although you can take steps to prevent oxidation, it is a naturally occurring chemical reaction that is impossible to prevent completely.

If the iron plating is still intact and you continue properly cleaning the tip, you should be good to go. However, if you notice cracks or holes beginning to form, you must replace the soldering iron tip. By this point, it is too late to fix it.

Things to Avoid to Maintain Tip Life

There are many ways to damage a soldering iron tip. A few common mistakes that are made and deserve to be mentioned are:

- Novices tend to use excessive solder because they think it will create a stronger bond. However, using excessive solder does nothing of the sort. In fact, it requires more heat and increases the workload of your tip, which in turn reduces its lifespan. Working smart can help keep your soldering iron tips working longer.

- When changing parts on your soldering iron, use the proper tools. This includes the tip. If you are having trouble removing a tip, do not force it, as merely dropping the tip can cause damage. Even if you do not directly damage it, the weakening of the iron makes other problems, like cracking, more likely.

- Even if you use a different object to clean our tips, such as a rag, make sure it is wet. While not everything will do as much damage as sandpaper, even using a dry sponge can damage the tip of a soldering iron.

Conclusion

Maintaining a soldering iron tip is not a simple task, but it is a manageable one. While you will not be able to protect your soldering iron tip forever, even with perfect maintenance, you can extend the lifespan a great deal by doing a few simple things. Be careful, use the right materials, and never forget to give your tips regular attention.

1 thought on “How to Maintain a Soldering Iron Tip”