“This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.”

Flux is often considered an essential tool for soldering to make a good soldering joint. But, welders in a pinch wonder if soldering can be done without flux.

Soldering without flux carries risks such as cold solder joints or oxidation of the soldering iron. However, soldering can be done without additional flux in two cases:

- If the solder already comes with flux incorporated.

- If the welder creates a simple homemade flux.

Soldering without flux can ruin a solder if you don’t know how to do it correctly. Read on to learn more about the role of flux in soldering and how you can go without it without ruining your joint.

Can You Solder Without Flux?

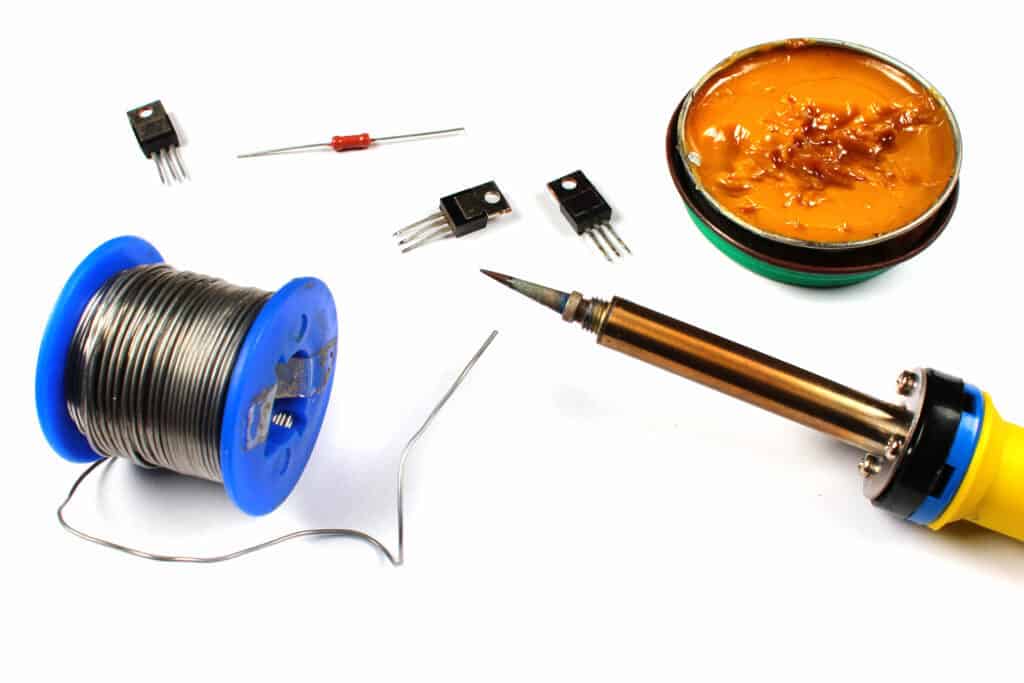

Some types of soldering can be done without flux. Most types of commercial soldering wire come with flux already incorporated into them in the form of a flux core. Flux cores in soldering can be broken down into two major categories:

- Rosin core: Rosin core solder is a soldering wire that already has a mild flux incorporated in its center. This type of flux is designed to be used on circuit boards or other types of electrical connections where it is impractical to remove flux residue. Rosin is unlike other types of flux in that it does not leave the connection vulnerable to corrosion. (Source: Harris Products Group)

- Acid core: Acid core solder is used for more heavy-duty soldering applications such as plumbing or steel soldering. Acid core solder is soldering wire with a central strand of flux material that helps to maintain a clean joint during the soldering process. Acid core solder is also useful for the connection of oxidized metals since the acid acts to remove oxidation. (Source: Mayer Alloys Corporation)

For soldering with a soldering wire that does not contain a flux core, soldering can still be done without commercial flux. This involves using a homemade flux along with careful preparation of the soldering materials ahead of time.

Why Do You Need Flux in Soldering?

In soldering, flux has one primary job: to clean the surfaces that are being connected with the soldering iron. The surface of many metal components quickly becomes oxidized. This oxidized layer on the surface of the soldering area can make it much more difficult to heat the area to the required temperature for a good solder connection.

If the soldering iron is used at a low temperature on an oxidized surface, this may lead to a “cold solder joint”—this kind of solder job will not be a good connection and can lead to either joint or electrical failure as a result.

If the soldering iron is used at high heat on an oxidized surface, this can lead to oxidization of the soldering tip. This, in turn, can cause the solder in your soldering iron to ball up instead of flowing smoothly, causing the soldering iron to malfunction. (Source: Metcal)

Can you solder without flux? It’s possible, but it also increases the chances that your solder is not going to go as planned. Since a consistent solder job can make or break an electronic component or a metal joint, using flux is usually the better option.

Soldering Can Be Done Without Commercial Flux

If you aren’t using flux core soldering wire, it’s still possible to solder without commercial flux if the materials are cleaned thoroughly before soldering, and a homemade solder is used. Soldering without any kind of flux at all usually results in an inferior solder. This will either render the solder useless or will cause the connection between materials to degrade more quickly over time.

Since most soldering jobs require that the metal joint or electrical connection is as clean as humanly possible to meet construction and materials engineering standards, flux is a necessary aspect of most professional soldering jobs. This is why you rarely see soldering done without flux.

Soldering is also nearly impossible to perform on oxidized metals without some type of flux. Without it, the soldering iron will either oxidize or not get hot enough to form a solid connection.

Non-Commercial and Homemade Flux Options

While most commercial soldering wires come with either rosin or acid flux cores, there are different kinds of flux available for those soldering wires or materials that don’t come with flux incorporated. Here are a few different kinds of chemicals that can effectively be used as soldering flux:

- Phosphoric acid: Phosphoric acid is a mild acid that is easy to find and can be used to clean circuit boards and other electronics before soldering. Experimentation is necessary to find a dilution of phosphoric acid that can clean effectively without eating away the coating on a circuit board. To prevent this, careful cleaning of the area post-solder is recommended.

- Rosin (pine tar): Rosin is used as a core in soldering wire, but rosin can also be applied as an external flux for prepping an area to be soldered before soldering is performed. Rosin can be collected from pinecones with denatured ethyl alcohol. It can also be bought in a commercial powder or grease.

- White vinegar and salt: A simple flux that can be created at home is a paste of white vinegar and water. This mild flux can clean some materials such as brass or copper but may be too weak for strongly oxidized surfaces or materials such as steel.

Using household items or easily sourced chemicals, you can quickly make a flux at home without buying soldering wire that incorporates it at the core. Soldering without flux may be possible, but it’s worth the time to mix some up for your soldering job to make sure it goes well.

What Happens if You Solder Without Flux?

Flux has a few other functions in soldering other than cleaning the components of oxidation. Another important function of flux is to “wet” the materials or prime them for soldering. Without wetting, electronic materials cannot conduct electricity as effectively. This also affects the ability of the solder to flow across the operating surface by facilitating heat conduction. (Source: Quora)

Without flux, a soldering job will not flow as consistently as it would with a proper flux, and this, in turn, can negatively affect the quality of the resulting solder job.

Flux is also responsible for protecting the soldered area from subsequent oxidation after the solder is completed. After a metal surface has been cleaned, this leaves it vulnerable to re-oxidation. Flux prevents the metal from being tarnished again by serving as a protective layer between the metal surface and oxygen in the environment.

How to Do Better Soldering Without Flux

Even if you don’t use flux when soldering, there are a few other things you can do that can help you get a better result out of your soldering job. Here are some tips for better soldering without flux:

- Keep your soldering iron clean. Your soldering tip is going to become oxidized over time, and this tendency is even worse if you don’t use flux. To counteract it, clean your soldering tip regularly with either a brass sponge or a traditional wet sponge. The advantage of a brass sponge is that a wet sponge will eventually shorten the lifespan of the soldering iron tip.

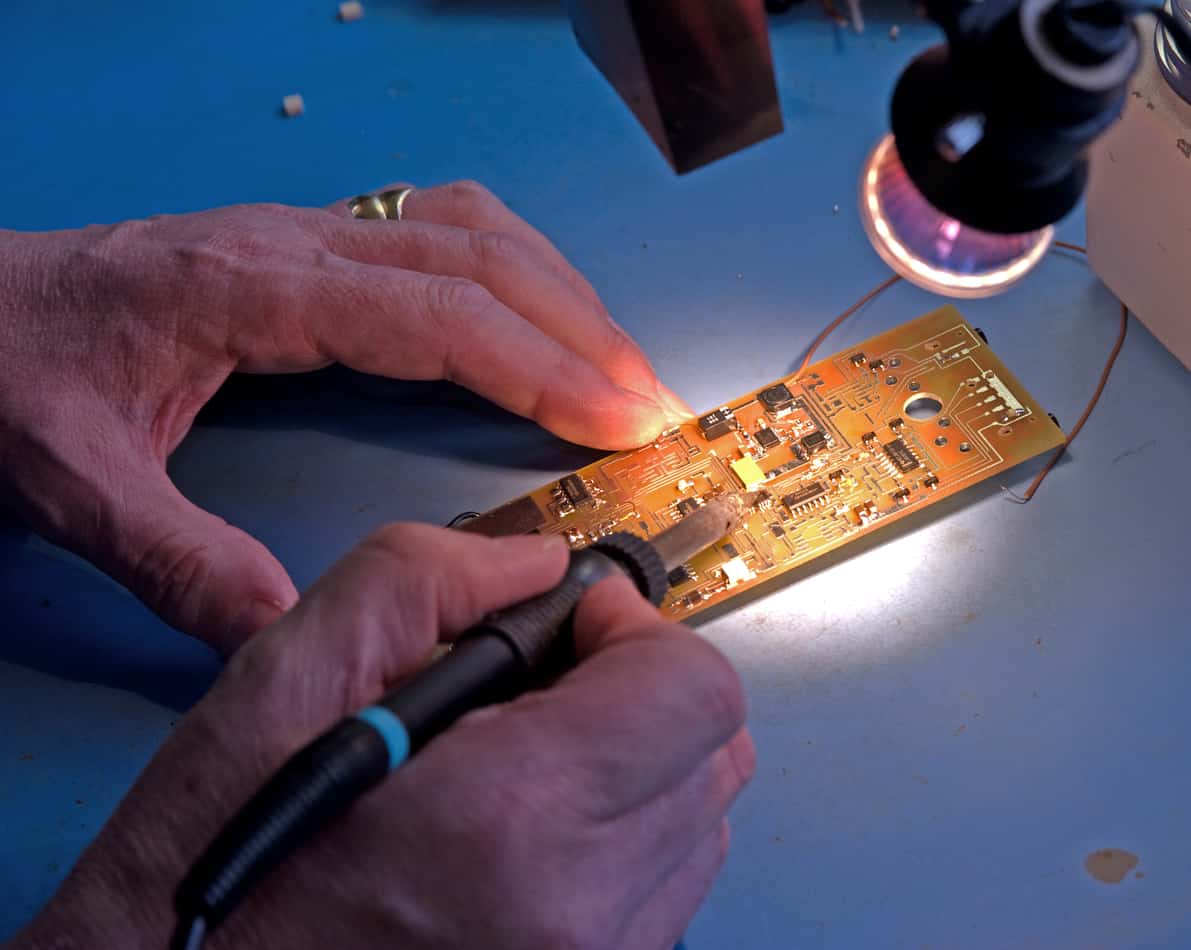

- Try investing in a helping hand station. A helping hand station can give you some stability and can hold your soldering operation in a particular position while leaving your hands free to manipulate the soldering iron. Many helping hand stations for solders also come equipped with strong lighting and magnifying lenses that make seeing the circuit board or joint easier.

Flux isn’t the only component that can lead to a strong solder job. Making sure that you are prepared with the right tools can help increase your chances of success.

Soldering Without Flux Isn’t a Good Idea

You can get away with using soldering wire other than commercial flux core wire, but there are several major disadvantages to soldering without flux. If you can swing it, even just using a homemade flux can make the difference between a poor solder job and one that lasts.