“This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.”

Soldering is a common form of repair for all different types of projects. By melting the solder material, you can use it to bind together two other metal wires or pipes. Solder gives you a powerful bond between the different components involved, which is why people prefer it. However, it can be challenging to know what kind of soldering material to use.

Both acid core and rosin core solder have distinct advantages and disadvantages, depending on the project’s components.

| Acid Core | Rosin Core |

| Best for plumbing projects | Non-corrosive |

| Bonds metal pipes and sheets | Best for circuit board applications |

| Leaves behind a residue | Does not leave behind a residue |

Typically, people use soldering for repairing plumbing or circuit board components. Determining the right type of solder to use for your specific project is vital. This article will address the differences between acid core solder and rosin core solder, when it is appropriate to use one or the other, and the benefits and drawbacks of each.

Acid Core Solder

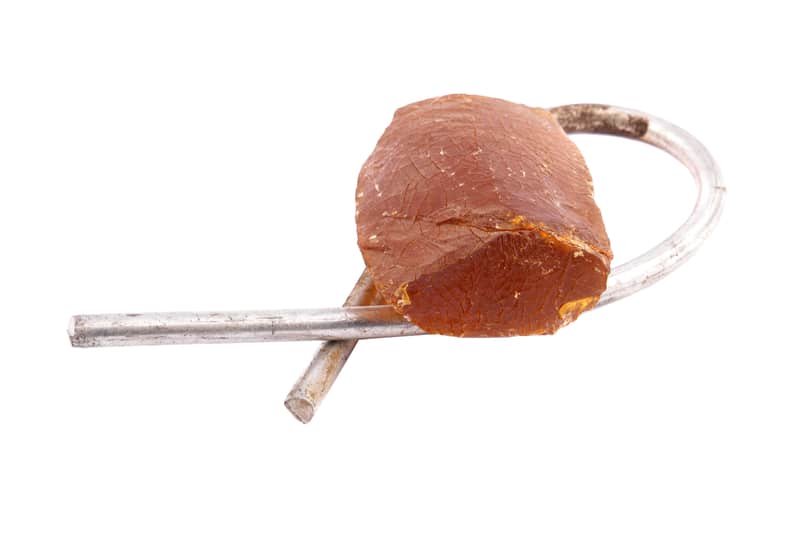

Acid core solder is generally sold as a metallic wire with a hollow core that is filled with a type of flux that is made from acid. Professionals often use solder flux in order to minimize the amount of corroding and rusting that the metals will go through after the bonding process. The use of a flux core enables the soldering bond to remain strong.

Acid core solder’s use of flux is beneficial for retaining a strong bond after the soldering process. Still, the flux residue must be cleaned immediately after you finish soldering the components. You can wipe it away with a damp cloth once the metal cools off enough for you to safely wipe it without disturbing the bonding between components.

This type of solder is typically used for plumbing projects, although people also use it to join metal sheets together. Depending on what kind of project you plan to use it for, the metal surrounding the flux core might be made of silver, tin, or lead. Each type of material works best in certain situations, but the center remains the same.

By incorporating the flux into the soldering material, you can save money and energy by not needing to buy and apply separate flux for your project. As the solder melts and starts to flow into space between the components and the flux flows with it to give your project an even application of both flux and solder.

| Pros | Cons |

| Suitable for steel and other metals | Flux residue must be cleaned after solder. |

| Best for plumbing | Should not be used for circuit boards |

| Excellent for bonding metal pipes or sheets | It cannot be used with aluminum |

Pros

The strength of the acid core flux helps the bond increase its strength. Because of the intense acid core flux, this type of solder can be used on almost any kind of metal. The versatility of acid core flux is beneficial if you want to use the same spool of solder on various projects around the house or if you are a professional contractor or plumber.

In addition to plumbing, acid core solder can be used by metalworkers, automotive manufacturers, aerospace engineers, and just about anything involving metal that needs to be joined. The aggressive cleaning abilities in acid core solder allow you to make a watertight joint when soldering together water pipes.

The acid core flux can dissolve even the harshest of oxidations and greases that might accumulate on your pipes or metal sheets. Professional plumbers and contractors enjoy using acid core flux because of the strength that it lends to the joined components and how long-lasting the solder will be.

Acid core flux can also be helpful when soldering pipes with small diameters. By etching and cleaning the surfaces thoroughly before joining them, you can ensure that you are not losing any of the pipe’s diameter by joining it. That way, you can stop blockages and other flow problems that may arise after you are finished soldering.

Cons

The acid core is corrosive and leaves behind some traces of residue after the soldering process. That remaining flux can lead to rusting and decreasing the strength of the bond and needs to be cleaned up after the joining process is complete. You can clean it away with a damp cloth once the pipes have cooled off enough to touch safely.

Water should be enough to clean away any remaining residue, as long as the water is hot. The active compounds remaining after the soldering process should be water-soluble. With a little bit of clean up, possibly involving some soap if the residue proves persistent, you can get rid of the residue, but it can be something of a hassle waiting for the metal to cool down.

You should especially not use acid core solder for projects involving delicate wires, both because the residue will be impossible to clean out afterward and because the harsh acid can damage the wires involved, even after the soldering process is completed. You do not want to see all of your hard soldering work going to waste.

The only metal that you absolutely cannot use acid core solder with is aluminum. Aluminum is a fragile metal, and the corrosive nature of the acidic flux will burn the metal and render it unusable. For aluminum components, you will need to use a more gentle kind of solder like rosin core solder.

Rosin Core Solder

Rosin core solder is very similar to acid core solder in that it is made of a hollow wire with flux inside. The metals wrapping around the flux are similar to the ones used with acid core solder. The essential difference is that the flux does not leave the same kind of residue with a rosin core as it does with an acid core.

In rosin core solder, the rosin is derived from the resin of pine trees and distilled into the flux that is used to strengthen the bond between the metals. The flux is still powerful enough to remove the oxides and other greases that might build up in the electric circuit without damaging the tiny sensitive wires that have been soldered.

Some types of resin core solder leave behind a bit of residue because the active components in those types are somewhat more substantial and clean away more of the grit and grime that might come between the two joints being soldered together. However, that corrosive quality makes those types of rosin core less appealing for many customers.

Rosin core solder has a more gentle type of flux inside than acid core solder, which means that rosin core solder can be used on fragile and brittle metals like aluminum. You will not have to worry that the rosin flux will harm the metals that you use it on or have to confine your project components to the more rigid metals.

| Pros | Cons |

| No flux residue left behind (depending on the type used) | It only works for copper and brass. |

| Best for circuit board applications | Produces a toxic fume when heated |

| Non-corrosive | It takes longer to heat |

Pros

The fact that rosin core flux does not leave behind a residue that needs to be cleaned makes it appealing for people who use it to connect small electrical wires. The tiny wires on a circuit board would be impossible to clean properly, so acid core flux would not be the right type of solder to use for a very small project.

As with acid core solder, the ease of using solder that has flux in the center of it far outweighs any of the cons. You can save time by using flux in your soldering and energy by not needing to clean it at all afterward. Saving the time and energy required to clean up after soldering is a great convenience for people who want to complete the project quickly.

There are three types of rosin cores to choose from in your solder:

- Rosin

- Rosin mildly activated

- Rosin activated

Mildly activated rosin is a more powerful cleaner of oxidation. Still, it does come with a severe drawback in the form of a slight residue left behind after the soldering process. Rosin activated is the most powerful of the options given, but it leaves behind the most residue after it is finished aiding the soldering process.

Most people choose rosin core solder expressly to avoid the need to clean up any residue after the fact. So, mildly activated rosin and rosin activated are not favored as highly as plain rosin. Most people prefer to use typical rosin so as to solder tiny electrical wires in circuit boards that are not easily cleaned due to their size.

Cons

Because of the non-corrosive nature of rosin core solder, it can only work for components that are made of copper or brass. This limiting factor means that the number of projects that you can use rosin core flux in is small, and a single spool might be more than you will ever need unless you frequently work with copper and brass components.

Rosin core solder releases an intolerable smell that can also be toxic for humans when it is heated—considering that most people are bent over their work and closely inspecting it, that puts your nose and mouth in the way of the fumes from the heated rosin. Wearing protective gear over your face can decrease your exposure to the fumes.

Although not deadly, the fumes frequently cause people to develop a cough, sore throat, or other difficulties breathing after prolonged exposure to the fumes from heated rosin core solder. Additionally, if the solder has any lead additives, the lead also produces fumes when heated that can get into your lungs and irritate them.

You should always use protective equipment when soldering, but ensuring that the space is adequately ventilated and that you are wearing facial protection over the eyes, nose, and mouth is especially important when using rosin core solder. Besides, some people are allergic to the rosin, and any exposure can result in severe symptoms like respiratory distress.

Does Rosin Core Solder Contain Lead?

This depends on the brand of solder that you purchase. Unless specified on the packaging as lead-free by the manufacturer, you should assume that rosin core solder does contain a small amount of lead. It is not enough to be harmful under most circumstances, but if you are soldering water pipes for potable water, you should choose lead-free.

However, if you are planning to solder metal sheets or other pipes that will not be transporting water anyone will be ingesting, lead is a convenient metal that helps the solder form a strong bond while still having a low enough melting temperature so as to not require a lot of extra time for the soldering process.

The Purpose of Flux Cores

While there is soldering material that does not have either an acid core or a rosin core, many soldering enthusiasts prefer to use soldering material that incorporates flux, a cleaning solvent that stops oxidation in metals and ensures a strong bond between the metals connected through the soldering process.

Although flux can be made of many different materials, the ones used in acid core flux and rosin core flux are quite trendy. The fact that solderers can save time, money, and energy by using solder with flux inside of it makes it all the more appealing. Under normal circumstances, flux is applied with a brush before the soldering starts.

Throughout history, flux has at times been made of charcoal, borax, and lime, as well as many other substances that prevent the development of rust and also dissolve pre-existing grime and dirt. Flux also helps with wetting, the ability for a molten liquid to stay connected to solid objects and not flow off the sides.

Flux has been in use for the entire history of soldering to get rid of the grit standing in the way between the two metal components being joined. In addition, flux can transfer heat between the liquid solder and the solid metal joints to make the soldering stronger after everything has finally cooled and any corrosive residue has been wiped away.

Is Silver Solder Worth it?

Soft solder is a soldering composite material that contains around 20% silver. Silver has a relatively high melting temperature for a soldering material so if you have a solder with a smaller amount of silver, it will not increase the temperature much. However, some soldering material has up to 30% silver in it, which increases the temperature significantly.

The upside of including silver in your solder is that it is a strong metal. Having a higher melting temperature means that when the silver cools and hardens, your joint will be stronger than if you used solder without any silver. When working on joints that need to be stronger, silver solder is definitely worth it.

On the other hand, if the joint does not need to be as solid, you could get away with solder that does not contain as much silver and also save yourself some money since silver solder is more expensive than other types of solder. Generally, you will see that the other components in silver solder are nickel or tin which are very soft metals with low melting temperatures.

Most solder contains at least 5% silver because it is such a convenient soldering material. Many people prefer to use solder that has a higher percentage of silver because of the strength benefits that silver brings to the project. However, the amount of silver involved may also increase how much time the project takes, as well as its expense.

Should I Add Flux in Addition to Flux Core Solder?

You might think that adding more flux on top of either your acid core solder or your rosin core solder can only assist the project, but it is generally recommended that you do not add any additional flux to your soldering project. One of the main purposes of flux is to dissolve grit and rust on the metal you are joining, but too much can degrade the metal itself.

Generally, a bit of extra flux on a project will not physically degrade the metal if it is a stronger metal, but it also will be a waste of flux because it will not enhance the joint or quicken the soldering process at all. If you have gone to the trouble and expense of buying solder that has flux in the core, you do not want to waste extra flux in the project.

In Summary

If you plan to use your soldering material for plumbing projects around the house, you are better off using acid core solder. For people looking to use their soldering abilities for more delicate electrical wires and circuit boards, rosin core solder will not leave behind any kind of residue that you will need to worry about.

Source

Types of Solder – A Thomas Buying Guide | Thomasnet.com

How to Prevent Soldering-Related Health Hazards | CableOrganizer (cableorganizer.com)

What Is Acid Core Solder Used For? | hunker.com

en.wikipedia.org/wiki/Flux_(metallurgy)

When to Solder and When to Braze Copper Lines: a Look at the Pros and Cons of Each | HVACSchool.org