“This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.”

When you have completed a nice, shiny TIG weld, it is a great accomplishment. Sometimes, though, they can turn out gray and dull-looking, and you don’t know why it happened or how to fix them.

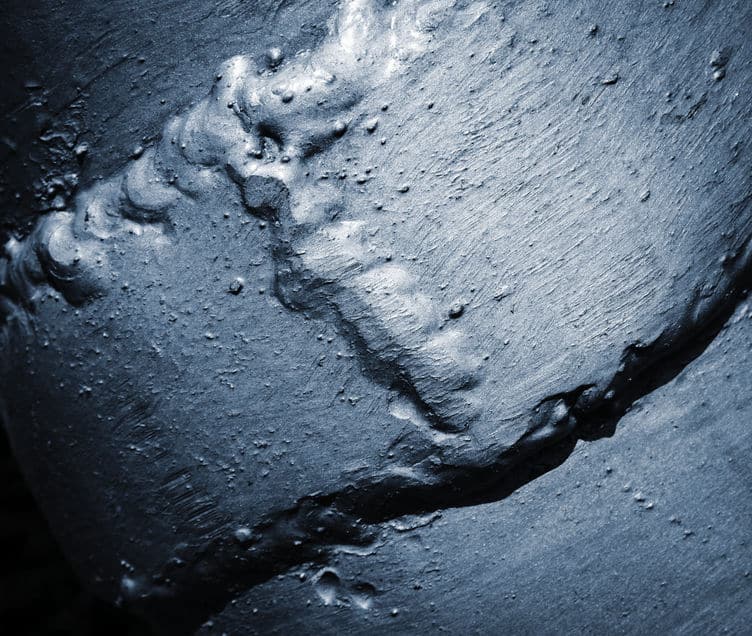

Why are your TIG welds gray? A TIG weld that looks gray may be a result of surface oxidation.

Tungsten inert gas (TIG) welding is often used to meet strict aesthetic, structural or code requirements. The TIG process is complex, and it is the most difficult process to learn. While the end result can create a beautiful looking weld, there are many things that can go wrong.

Judging TIG Quality

TIG quality is usually obvious, as the appearance of the bead is going to be a good representation of it. A more significant inspection of the weld shouldn’t be necessary in most cases because of this. The use of quick visual inspection is more comfortable, as well as time-consuming and expensive.

Using this inspection method is going to allow you to gauge whether the weld is acceptable quality. The things to look for in this inspection are the attractiveness of the weld, but also visible signs of weakness. If not, this can give you a good idea of what problems you may have to work against when trying again.

Knowing the difference between a properly weld job and something wrong isn’t always easy, however. To understand this better, we have to know what a good looking weld is and how to properly accomplish it.

How Do You Achieve a Good Looking Weld?

If you are thinking that your weld may not look as good as you might have expected, you first need to understand the basics of how to make a good looking weld.

- The base material being used should be completely clean. Remnants of paint, rust, or oil can often be found on the metal and should be checked before use and cleaned according. Cleaning should be done with brush or grinder.

- Make sure that the proper grounding connection is being used.

- Check to see if the area that is being used for the weld site is well ventilated. Improper ventilation can cause unwanted gases to interfere in the weld’s quality.

- Proper voltage is a very important part of the welding process. The voltage levels needed for your job are directly tied to the material being used. Have a good understanding of what voltage works best with the base metal that you are using before starting the job.

- Using the correct shielding gas is possibly the most important thing to remember when it comes to having a nice looking weld. Each kind of shielding gas is going to be based on the base material being used, so make sure to check that as well.

- Making sure that you have the correct size and type of electrodes for the job is going to help avoid any mishaps. There a few different types of electrodes, so be really sure that you know which to use.

During a TIG weld, there needs to be a good bit of control involved. This is especially true when talking about thinner materials being used. Arc stability should be a top priority, as well as current control. Thankfully, with more portable machines, this can be a lot less difficult than with standard transformer welders.

When the material heats up, its structure changes. When the heated metal is met by the surrounding atmosphere, the elements in the air can cause chemical reactions.

The colors that result, sometimes gray, depending on the makeup of the metal, the atmosphere composition, the temp where they meet, and the duration of time the metal is exposed at the elevated temperature. What is happening is called oxidation.

What Are Different Types of Oxidation?

During TIG welding on steel materials, surface oxidation can result if insufficient protection from the atmosphere, moisture or surface contamination is present. This can cause various degrees of oxidation, including the following:

Burn-Through

When protection from the atmosphere is not sufficient during the welding process, various surface conditions can result.

Continuous severe oxidation or burn-through is typical of inadequate shielding gas coverage or moisture present. This results in a rough surface profile and a dark gray, massively scaled surface appearance.

Sugaring

Another issue with oxidation, usually indicating poor backing gas coverage, is sugaring. This can leave a weld with a very dark gray, almost black coloring and a granular or wrinkled surface appearance.

Heat Tinting

Many metals and their alloys produce a very thin, adherent layer of oxide on their surfaces when exposed to elevated temperatures in the atmosphere.

These oxide layers are dull gray for most metals and are known as heat tinting. Heat tinting occurs around fusion welds made in steels, stainless and titanium and its alloys, particularly in heat-affected zones (HAZ).

What Causes Oxidation?

Shielding gas, typically Argon, is designed to protect the hot welded area from the atmosphere until the bead and HAZ have cooled below the point where the atmosphere won’t affect the steel’s properties.

The gray color (along with a number of other colors) is caused because the metal is too hot after the shielding gas is removed from it. The weld was then allowed to absorb impurities from the atmosphere, changing its color and possibly its integrity, including reduced strength and ductility.

How Do You Fix Oxidation?

Oxidation happens because of an excess of oxygen, as the name suggests. This is only really a problem if there is a lack of shielding gas or if the wrong shielding gas is used.

Oxidation can affect the appearance of the weld, changing its color completely. It can also weaken the weld and make for an overall lower quality job. Unfortunately, when oxidation occurs, there usually isn’t really any way to fix it. This means that the job is going to have to be started entirely over, which can definitely be a hassle.

There are a few ways to prevent this from happening, however. The first thing to do is to make sure that there are no remnants of oxygen near the weld area. This is referred to as purging. Then the next best thing to do is to ventilate the area.

Without the welding area properly ventilated, oxygen will be trapped in the room, along with whatever shielding gases you may be using. Not only can this be bad for the weld, but it can also be dangerous for the welder. Making sure that the room is properly ventilated is definitely a priority.

How to Check:

Surface oxidation can be eliminated when the atmospheric air is correctly displaced by an inert shielding gas, such as Argon. Before starting the welding process, though, you should always check that it is not the gas itself that is causing the contamination/oxidation issues.

- When choosing shield gas, make sure to look at the cylinder label to be certain that you are using the right type of gas for TIG welding. This is usually a pure Argon. Attempting to weld with an Argon/CO2 mix will cause immediate contamination.

- You’re going to need to know the CFH of the shielding gas before starting. For TIG, this should be around 18 CFH. Don’t assume that a higher gas flow rate provides greater protection and coverage. Excessive flow creates turbulence that pulls in unwanted airborne contaminants.

- Check any areas that could possibly cause a leak, like openings in the hose. A leak can cause the weld to be contaminated, due to the access air from the surrounding atmosphere. To find out if a lead is present, rub soapy water over the hose and any fittings.

- If you have a full cylinder, the right gas, and no leaks, you may have a tank that is contaminated with moisture.

What Are Other Issues with Weld Appearance?

The weld bead is supposed to bond with the metal, creating a strong bond with the right amount of fusion and penetration. In TIG welding, it is also important that the weld is clean, good-looking and the same color as the base metal, inside and out.

Even if you make sure that your base materials are clean, stack your welds nicely and minimize spatter, contaminated welds can sometimes happen. With oxidation, these welds can change color – and not just gray – but anything from gold to green to purple. Some artistic welders may prefer these colors, but for other industrial applications, most are unacceptable.

There are other issues with weld appearance that cause problems, as well.

These include when the weld bead…

- Is too wide – Reduce amperage.

- Is too narrow – Increase amperage.

- Is convex in shape (rollover) – Increase amperage, slow down or increase arc length.

- Is concave in shape – Add the filler, slow down or check root gap.

- Is irregular in shape – Make sure heat input isn’t marginal on check travel speed consistency.

- Is undercut – Shorten arc length and adjust electrode angle.

- Has a lack of penetration/fusion – Check heat input, increase amperage or decrease speed.

- Has excessive penetration – Reduce amperage and reduce root gap.

- Has arc strikes – Adjust or correct your welder.

Final Thoughts

Making mistakes during a weld can be devastating. Many of them can’t be fixed after the fact, but they can be prevented.

Preventing your welds from becoming gray and unsightly is as simple as understanding the weld job itself. As long as you know how to weld your materials properly, preventing any mishaps comes naturally.