“This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.”

Especially if you are new to TIG welding, you might have encountered the “balling up” of your TIG electrode. A TIG electrode normally lasts a while before it needs to be sharpend or replaced, so if you experience melting on your electrode, this article might help you to shed some light on the issue.

TIG electrodes melt due to a variety of reasons, the most common are: diameter of the electrode too small for set current, the polarity of the torch is clamped electrode positive, welding with DC instead of AC or the electrode material is not suitable for the welding setup.

In the following article, I will go into a bit more depth for these main causes which hopefully helps you to fix your electrode problem!

Background Information (First time welders start here)

To understand why your tungsten tip is melting, we should have a brief look at the underlying principles in Leymann terms to be in a better position to narrow down the cause of the problem. If you are already fairly familiar with the physics behind tig welding, feel free to skip to the next section.

In TIG welding, electrones are travelling between the electrode and the workpiece through a so called arc. This arc is a plasma that allows the electrodes to travel. Note that the shilding gas you are using is helping to create this plasma, and makes it much easier to form than in “regular” air. The electrodes can either flow from the torch to the workpiece (which is called electrode negative) or from the workpiece to the torch, which is calles electrode positive. I will get into more detail on the polarity and its effect in the polarity section.

And last but not least, we have the choice between alternating current (AC) and direct current (DC). When utilising direct current, the welding setup is either electron negative (DCEN) or electron positive (DCEP). It gets interesting though when you use alternating current, because that is basically sending electrodes in both directions for a very short period of time before switching to the other direction of flow. Alternative current welding is generally utilised for aluminium welding. More in the next section. But before I lose myself in the technical details, lets get into the practical stuff.

Why does my electrode melt when welding Aluminium?

When you weld Aluminium, you will face an additional challenge which you are not encounting when you are welding most ferrous metals. Aluminium has an oxide layer that reforms in split seconds when exposed to oxygen (air). This is a bit like a protective rust. That is why Aluminium is not rusting like iron, the oxid layer protects the Al from direct contact with environmental oxygen (e.g. air). But for welding, this layer has to be removed, otherwise your weld results will be poor at most. The beads will look everything but shiny and even, and contamination with oxides, which are harmful to the mechanical properties of your weld, are certain. Also oxides are ceramics, which have a melting point at around 2000°C in contrast to 660°C melting point of Aluminium itself. Just by looking at the numbers you can see that you will hardly be able to create a nice weld pool with these two contrasting elements.

So whats the fix? Breaking the oxide layer up! Basically, what you can do through setup is using the TIG torch as an electrode shooting device, which breaks ups the oxide layer. This cleaning mode allows to remove the oxides and weld the aluminium. Do not mistake, the oxide layer will be back the moment you stop welding that section, but this is sufficient for welding purposes and actually helpful for rust protection as mentioned above. For more details on the influence polarity has, check the polarity section.

Polarity – Pole it right!

When you are welding and your tungsten tip is balling up or melting, chances are high that you have the polarity wrong. When the electrode is poled electrode positive (DCEP), the tungsten tip will be heating up quite quickly, generally visible through glowing colours. If you are welding direct current, and this is happening to you, change polarity to electrode negative (DCEN). That should do the trick if polarity for direct current welding was your issue.

If welding Aluminium, welding with alternating current (AC) is recommended. Not every welding plant has this feature, so if you can’t find how to set AC on your welding plant in the manual, than this plant is not suitable for Aluminium welding. On the other hand, if your machine is set on AC and you still don’t get the desired results, check the next section for the right balance.

Balance – finding the right one

The balance setting is responsible for the ratio between electron

Electrode size matters!

Whatever you

Using different Electrode materials for better results

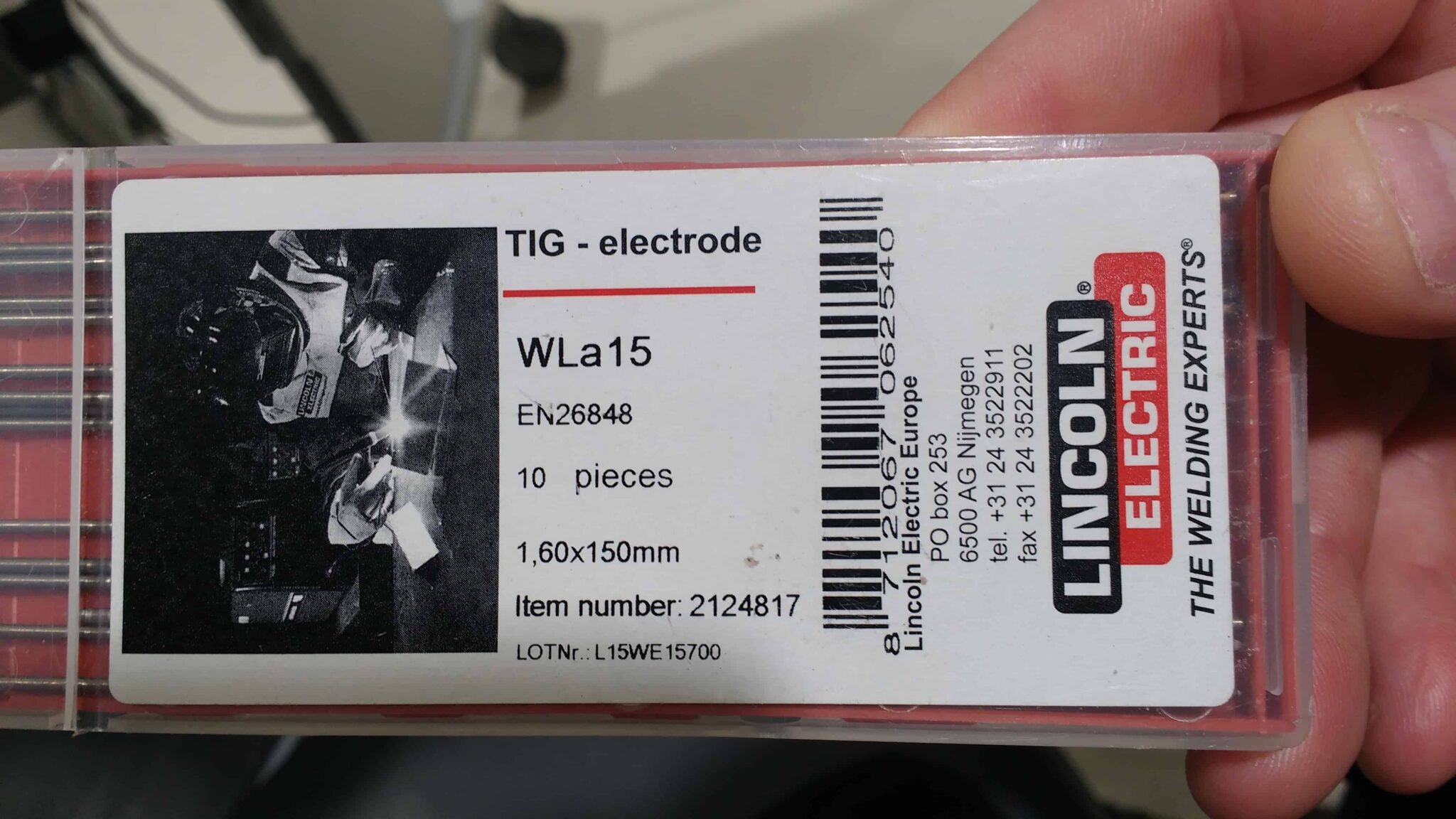

Similar underlying principle than for changing the electrode diameter would be changing the electrode material. Using Thorium, Cerium or Lanthanum in your tungsten gives you higher heat resistance, but it comes at a cost (financially and regarding the welding properties).

These were a couple of the most common resons why your tungsten is melting. Please keep in mint: This article can only explain the general principles, details may vary for different welding plants! Hope this helps you fixing your problem. Write me a comment if you have feedback or questions.

1 thought on “Why does my TIG electrode melt?”