“This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.”

College tuition prices continue to trend upward, and many young people are considering alternatives to the traditional college route. As trade schools become a more popular option, many people are thinking about going into welding–but welding isn’t for everyone. There are some very good reasons not to become a welder.

While welding may seem like a stable career option, it’s not the right choice for everyone. Here’s why:

- Dangerous

- Long hours

- Welders earn a low salary

- Physically demanding

- Competitive job market

- Extreme environments

It’s essential to take the risks of a trade into serious consideration before starting down a career path, be it an apprenticeship or trade school. Understanding the downsides of an industry is the first step towards choosing a career that is in harmony with your natural strengths and weaknesses.

This is Part 2 of my Pro/Con becoming a welder analysis. If you interested in reasons why you SHOULD become a welder, make sure to check out the pro list here.

Welding Is A Dangerous Job

Any career that places workers on a construction site is going to be accompanied by its share of on-the-job dangers. Welding, according to labor statistics, is among the more dangerous trades available. There are many ways to get hurt as a welder and very few ways to avoid it.

Welders Are Prone to Burn Injuries

Welding is done with a powerful blow torch, used to melt steel and metal components and fuse them inseparably. Naturally, a flame that powerful causes severe damage if inflicted upon human skin.

Welders wear a lot of heavy protective gear when they are working, but that does not completely negate the potential for injuries.

Over time, according to experienced welders, you build up a resistance to the minor burns that are so common in a welding career. Over time, however, as the damage builds, it can lead to longer and more problematic health and mobility concerns.

Welders Are Exposed to Dangerous Heights

Commercial welders are often required to work on pipes and welding systems for buildings under construction. For example, if you are employed to lay welding for the 27th, or 127th floor, you may be required to work at dangerous heights. Some welders use scaffolds, while others work suspended on platforms.

As with construction work and other injury-prone workplaces, welders do have access to standard satiety precautions. In addition, employees working in dangerous environments are provided with and required to wear hard hats while on the job site. Welders are required to be adequately trained before entering a dangerous commercial work area.

Confined Spaces

Aside from the potential for claustrophobia, working in confined spaces comes with a set of additional risks.

Working in a tight space restricts your range of motion, which can be dangerous when using power tools such as soldering irons or circular pipe saws. At the very least, welders can expect a number of bumped heads, knees, and elbows, if they’re lucky.

Most of the workplace injuries that happen in welding jobs consist of cuts and burns from tools. It stands to reason that working in awkward, uncomfortable positions increases the likelihood of a user error resulting in an injury.

As well as increased risk of tool injuries, working in tight spaces is hard on the body. Welders’ joints suffer from hours spent hunched under a leaky pipe or bent in unusual positions to reach a specific point.

Hearing Damage

Many welders suffer from early loss of hearing, damage to their eardrums, or even tinnitus due to years of exposure to the sound of power tools. Because so much work is done in tight spaces, the risk of hearing loss is higher than if you were working with tools in open spaces.

The risk of hearing loss can be somewhat mitigated by using earplugs or industrial noise-canceling headphones. These options, however, come with their own risks and downfalls. For example, over-ear headphones run the risk of being caught and snagged in cramped spaces.

Also, restricting hearing with earplugs may prevent welders from hearing crucial instructions or safety signs.

Radiation Exposure

According to Osha, one of the most serious health and safety concerns associated with the welding industry is exposure to radiation. Welders, in the course of their duties, are frequently exposed to fumes and ultraviolet (UV) radiation.

The dangers of radiation exposure can be mitigated by the proper use of Personal Protection Equipment. Still, there’s no getting around the fact that a career in welding means constant exposure to radiation, which increases the risk of health problems later in life.

Equipment Related Injuries

The most common workplace injuries in the field of welding, according to the Bureau of Labor Statistics, involve tools and equipment. Aside from the actual welding torch, welders need a wide variety of tools over the course of their career, each of which is potentially dangerous in its own manner.

Aside from the customary scrapes, bruises, and burns that a welder might acquire organically on the job, there are a number of more serious and even fatal injuries that can occur when tools are not properly handled.

Welders are frequently burned using soldering irons. Unsurprisingly, burns are the most common workplace injury in the field of welding.

Among the more serious injuries attained by welders, the frequent necessity of pipe saws and other cutting tools makes for a high risk of injury. When working in dark or uncomfortable positions, it is relatively common for even an experienced welder to slip. A mistake with a pipe saw can often end in an amputated finger, if not more.

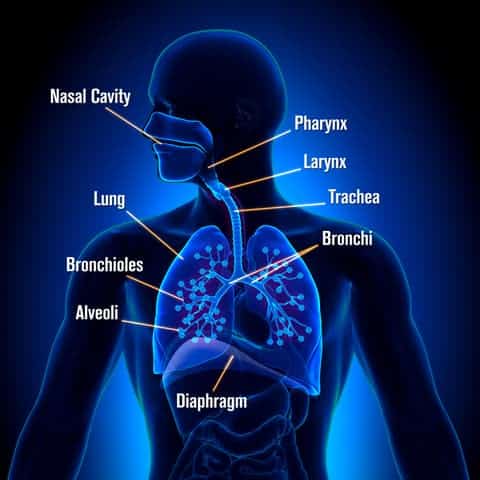

Respiratory Damage

welders work often takes them into the attics and crawls spaces of houses. If the house is not up to code, as can often be the case, welders run the risk of being exposed to materials now known to be dangerous.

Welders working in old houses are often exposed to asbestos and other chemicals, which can cause long-term respiratory problems. Asbestos specifically is now known to be the cause of mesothelioma. Asbestos is also one of the leading causes of lung cancer, and direct exposure is almost as dangerous as cigarette smoking.

Welders can also suffer respiratory damage from directly breathing fiberglass insulation and other components or chemicals found in crawlspaces.

Welders Work Long Hours

In order for welding to be a profitable and sustainable career, welders have to put in long hours. Due to the nature of the industry, welders often have to travel long distances for certain jobs.

When work needs to be done on a cargo ship or an airplane, the welder travels to the job rather than shipping a metal of that size and scale.

Along with lengthy hours, the constant travel makes planning and regular life stability difficult. Welders must follow the work in order to keep earning an income, which provides an unstable setting for building a life outside your career.

Welders Earn A Comparatively Low Salary

Most people can agree that welding is an important job. Welding is used on the wings of airplanes, cargo ships, military vehicles, and even in the construction of artistic metal sculptures. The value of a welding career, however, is not fully reflected in the annual salary most welders take home.

According to the BLS, the average salary for someone in the welding industry is roughly $44,000 per year or $21 per hour.

These are relatively good wages, depending on the state and your cost of living, but welding doesn’t provide the same financial security offered by other industries.

It is important to weigh the inconvenience, instability, and unpredictability against the tangible reward. If you’re choosing a career in welding, it’s crucial to know you won’t be netting high figures, especially in the beginning.

If you take on a trade career, you will earn more than a career in a minimum wage environment. The average annual wage for cashiers, for example, is roughly $22,000 to $35,000. Because welding is a skilled trade, requiring training and certification, the average salary is higher.

However, it is important to consider whether the extra $10,000 per year on average is worth the danger and instability of a competitive welding career.

The Welding Market is Highly Competitive

Welding is a hot trade with a lot of demand all over the globe. If you’ve got the right skill set, along with the right toolset, there will be no shortage of work.

The welding industry, however, is very much reliant on keeping abreast with the advancements in welding technology.

For example, the most common method of welding done today is arc welding, which runs a current through the metal, heating it until it is malleable enough to work with. Welders who are not trained or in possession of the proper equipment to do arc welding will find the competition in the welding job market unforgiving of alternative methods.

It is not impossible to make a living as welder if you don’t have the latest equipment, but you’ll have to fight for every cent you earn. With so many people turning to trade schools as an alternative to college, where they are trained in the latest methods, the job market is flooded with young talent.

Welding Is Physically Demanding

While undoubtedly a skilled trade, it’s also important to remember that welding is hard manual labor. Welders must spend hours crawling in tight spaces, carrying heavy tools and equipment, climbing, and using heavy machinery.

Welders’ bodies (especially their hands) are prone to occupational wear and tear, as any career welder will tell you. No matter how experienced, all welders can expect a few burns over the course of their careers. While usually topical, requiring nothing more than basic first-aid at most, the repetition of minor injuries over time has a long-term effect on the health and mobility of your hands and arms.

Similarly, many experienced welders complain of the damage to their joints. Years of repetitive kneeling and crawling make joints prone to arthritis and other damage.

If you are not in good physical condition, welding can be dangerous or even lethal. Welders should be capable of being on their feet or crawling for hours at a time and lifting heavy weights regularly.

Many welding injuries are incurred by improper lifting techniques, resulting in spinal damage or muscle trauma. Ladders and scaffolds also provide the danger of slipping and fall-related injuries.

On top of the physical strength required by the job, welders are also exposed to the elements. Working in cramped spaces, in rain, snow, flood, or heat can be demanding on the body and lead some welders to burn out early.

Welders Are Exposed to Extreme Environments

The requirements placed on a welder can be extremely demanding. In cases where a welder must work on an immovable vehicle, such as a Naval aircraft carrier or even the International Space Station, they must be able to adjust to the environment around them.

Not every welding job is going to require a spacewalk or a scuba tank, but some do. Even if you’re not fixing the bottom of a submarine, the likelihood that you will have to work in inclement weather conditions at some point in your welding career is high.

Conclusion

Any profession is going to have downsides. Understanding what makes a job difficult or even dangerous is crucial to know if it is the right job for you. When making a career decision, considering the unpleasant realities that go along with a job is just as important as considering the salary and location.

That being said, welding can be a long, fulfilling, and profitable career for someone properly suited for the work. Welding Unions across the country are notoriously strong, and the path from apprenticeship to journeyman is available to anyone willing and capable of putting in the work.

If, however, any of the problems listed in this article seem like they would pose a problem for you, then you would be wise to consider another trade. There are other trade options with less (or at least different) risk which can also provide job stability and a sustainable income. Consider your options weighing your strengths and weaknesses equally before embarking down your career path.

This is Part 2 of my Pro/Con becoming a welder analysis. If you interested in reasons why you SHOULD become a welder, make sure to check out the pro list here.

Sources

The Disadvantages of Being a Welder | Chron (work.chron.com)

Welders, Cutters, Solderers, and Brazers | U.S. Bureau of Labor Statistics (bls.gov)

Pros and Cons of Being a Welder | Alot (careers.alot.com)

Hazards and Solutions | Occupational Safety and Health Administration (osha.gov)

2 thoughts on “Is Welding a Good Career? 6 Reasons You Should NOT Become a Welder”