“This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.”

Making marks on metal is an important part of producing accurate metal work. But unlike wood and other crafting materials, it is not so easy to get a visible line to stay on the surface. You will need to consider what type of metal you are working with, as well as the tools that you are using on the metal, and what sort of project they are best suited for. How do you mark on metal and what are the best methods for marking your measurements?

There are several methods for marking measurements on metal. In the list ahead we’ll explore the best types of tools and give some tips on how to mark a type of metal based on its specific hardness or physical qualities as well as the best way depending on the needs of your project.

Mark Metal with a Permanent Marker or Sharpie

This method is by far the most simple and straightforward. There is a good chance you may already have a permanent marker and maybe you are now reading this because you had some trouble. If a permanent marker or sharpie did not work for you previously, it was likely that there was a residue, dirt, dust, or maybe some type of oil or lubricant on the metal.

If the metal you are working with is new and clean, there is no reason that you can’t simply make your mark with a permanent marker. As long as you give it a moment to dry, the marker won’t rub off easily. If this doesn’t work you can clean the metal off and try again or you can try another method.

Another problem you may run into with the permanent marker is that they will generally not produce very fine lines. When a permanent marker just isn’t doing the trick or maybe yours has run out of ink, there are additional options to make simple markings when working metal. And fortunately, none of them are too technical.

Etching Metal with a Scribe

NEPAK 4 Pack Tungsten Carbide Scriber with Magnet,with Extra 4 Replacement Marking Tip,Etching Engraving Pen for Glass/Ceramics/Metal Sheet

If the permanent marker is just not going to work for you, another option is to use a tool called a scribe. This method may not work for every metal project you work on because it scratches the metal, But it will be a perfect option if your plan is to cut or grind the metal at the marked point.

A scribe can be used for all kinds of purposes, but its primary use is to scratch lines into metal. The tool in its simplest form is a metal spike. Sometimes they have handles or are built into pens, some of them are made into compasses in order to mark circles.

An advantage to using a scribe over a permanent marker is that it will typically be more precise and mark a cleaner line. The only problem that some find with the scribe is that sometimes the line you scratch into the metal is too faint and can be difficult to see. If you find this to be the case, then the next method might help with the problem.

Use a Scribe and a Permanent Marker on Metal

Sharpie Permanent Markers Variety Pack, Featuring Fine, Ultra Fine, and Chisel Point Markers, Black, 6 Count

When you’re unable to clearly see a marking from a scribe and the permanent marker is not producing accurate lines. Using the two of them together may provide an excellent solution.

To accent a mark from a scribe, scribble a patch in the general area where your measurement is. Once you have a patch of permanent ink, get your measurement and use a scribe to scratch a line through the ink and into the metal. This will result in a much more visible line produced by the scribe.

This method will still require the sharpie to not get rubbed off easily. If you find that you are having too difficult a time keeping track of your markings because of this, then you may find another product more helpful.

Marking Metal With a Soapstone

Soapstone is commonly used by welders when they need to make marks on the metal they are working on.

Soapstone can be used for marking metal and is a natural material similar to chalk, which can also be used for marking. However, the main difference is that soapstone will not burn from the hot temperatures of welding and will be slightly more difficult to accidentally wipe away.

While the markings made with it are resistant to heat, it is still easy enough to wipe away or erase with a wet rag. Soapstone can be purchased as a pen or marker type of applicator or in its raw form.

Silver Streak Pencils For Welders’ Marking Metal

Metal Marker with 6 Refills, Round (Silver-Streak)

Another good tip for welders is to use a silver streak pencil or pen. These pens are similar to soapstone in that the markings they make will not burn off or be easily wiped away. They will also write on dirty metal unlike a sharpie or permanent marker.

Markal makes a version of a welder’s pencil that can be purchased in silver or red. This product claims that it will not be easily wiped or blown away and it also has the great feature of being reflective during welding, which will make it easier to see when the user has a mask or goggles on.

Silver streak pencils like the one made by Markal can be sharpened the same way that a regular pencil can be and can be purchased in multi-packs.

MetalHead Paint Markers are Permanent on Dirty Metal

3 Pack – Black Valve Action Metal Paint Marker U-Mark, Made In USA

If you want something a little more specialized for metal than a permanent marker, there are multiple products out there specifically designed for writing on metal surfaces. One of these is a paint marker made by UMARK called MetalHead.

UMARK describes their METALHEAD product as “stubbornly permanent”. It comes in a squeezable, refillable bottle, and it is touted to be perfect for permanently marking difficult materials like,

- Rusty Metal

- Greasy or Oily Metal

- Damp wood

- Concrete.

There are many applications for the METALHEAD marker, and it is perfect for construction, wood and metal working. If you find that you would like a more precise application of the METALHEAD paint marker, you’re in luck because UMARK also makes the METALHEAD2, which is the same great product but with a fine tip.

Using an Engraver to Mark Metal

An engraver is a great tool that can be used beyond simple measurement markers. There are several types of engravers. If you use one in combination with a straight edge, it can do the same job as a scribe but an engraver is capable of more. If you are looking to go beyond simple marking lines, this tool might suit you better. A simple hand engraving tool like this one by VQVYBXN, costs about $26.

A hand engraving tool works similar to a drill, rotating rapidly but with a smaller, precise bit, making tiny scratches. These tools can be wireless and come with a variety of bits. Many craft workers and artists use engravers for finishing details and design work.

While an electric engraver is more precise and more capable in marking designs or writing into metal than a scribe, it still may not be the ideal option depending on what you are trying to etch into the metal. The main limitation when it comes to what you can design with an engraver is what your artistic ability limits you to. There are several other machines available that can deliver professional, commercial grade engraving/etching for a relatively affordable cost.

Automatic Engraving with a CNC Machine

For marking on metal outside of cutting measurements, there are many options as well. A CNC machine or Computer Numerical Controlled machining is a type of printer or router that works through a computer with special software. Using this programming, a CNC is able to follow a detailed plan and can engrave basically any writing or pictures into a piece of metal.

For someone who has an engraving or is machining business, owning a CNC is a great investment. An affordable CNC router can cost as low as $200 and should be able to engrave aluminum as well as other materials. Most of them include:

- Operating software

- Router bits

- Plate Clamps

Although a machine like the GENMITSU 30-18 PRO is relatively affordable, it does have its limitations. The price you pay for a machine will go up depending on what metals you want to be able to engrave and remember, even though it comes with the software, it does not come with a computer.

Letter Punching Metal for Serial Numbers and Initialing Property

If your goal is to put a few simple letters or numbers into metal, a letter punch is a good option. A Letter punch is a metal punch used with a hammer to set a specific character or number into metal. A set of these punches like this one goes for about $20 and will typically contain all 26 letters of the alphabet, numbers 0-9, plus maybe a couple of extra symbols.

Each punch has an individual character or number molded onto the end. The character is mirrored and when the stamp face is placed against the working medium, the butt end of the punch is hammered and an imprint will be left in the metal.

Letter punches are a tool commonly used by machinists and fabricators. They have a limited range of use, but they are great for initialing property or putting serial numbers into a finished product.

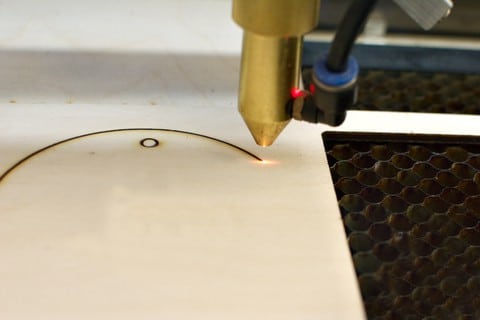

Laser Engraving Metal for Precision on Engraving Metal

If we move up in the price range of engravers we can find machines that are not only capable of engraving more types of mediums but also CNC machines that use more advanced technology. Some of these modern machines use lasers to burn engravings rather than bits which grind or cut engravings into their medium.

A laser is an extremely precise instrument that is capable of precision engraving. Using a laser rather than a traditional CNC can have several advantages,

- A laser will not wear out like a bit will.

- Speed

- Depth of the engraving

- Uniform consistency between products.

Laser engravers are probably the most expensive option of any of the products on this list, but there are relatively affordable options and they will still create professional looking and consistent engravings. If your goal is to mark your cutting and welding measurements, this machine is far more than you need.

Acid Etching as a Metal Permanent Metal Marker

For your products that are already cut, welded, brushed and polished, there is an additional touch you can mark metal with that will add an incredible finish. It is estimated that acid etching has been around for at least 5000 years, although some of the finest examples come from the Renaissance era.

Intricate designs are acid etched into metal by,

- Covering the surface of the metal in wax or varnish.

- A design or picture is scratched into the wax, leaving a picture exposed in the bare metal.

- From this point the metal is submerged in corrosive acid.

- The metal is pulled out and cleaned off; the design that was put into the wax will remain on the metal’s finish.

- The longer the metal is left in the acid, the deeper and more defined the image.

Acid etching is a complicated art form that has begun to reemerge in recent years. It may take years to learn. This is a simplified explanation but it should be noted that extreme care must be taken when working with highly corrosive chemicals.

Conclusion

Perfect means of marking metal depends on what your project is and what results you need. Marking measurements in metal for cutting or welding is much simpler than engraving or putting designs into a finished product. Whatever your project is, these tips can hopefully shine some light on the different options that are available to metal workers that need to mark their medium in various ways.

Sources

How to Etch Metal | Industrial Metal Supply Company (industrialmetalsupply.com)

Laser Etching Metal: All You Need to Know | All3DP (all3dp.com)

How to Mark Metal | 5th Street Fab

Silver-Streak & Red-Riter Welders Pencils – Pack of 12 | Markal (markal.com)

What is Soapstone Used for in Welding? | Weldingheadquarters.com