“This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.”

If you have been thinking of getting started in a new career and like the sounds of welding, then here is how to become a welder by a welder!

If you enjoy working with your hands and you’re not afraid of confined spaces, working at heights, hot weather, cold weather, and getting completely filthy with the occasional burn thrown in, then welding could be a great career choice for you.

Generally, becoming a welder includes three main steps: Finding a suitable industry, identifying the required welding certifications for that chosen industry, and practicing welding to pass the necessary certification, ideally in a hands-on environment.

Depending on where you live in the world, becoming a qualified or certified welder is going to be a slightly different yet similar experience. In the following article, we’ll take a look at the basic steps needed to become a welder and even one welder’s personal story.

What Makes A Welder A Welder?

A welder uses various welding techniques to weld together various metals, including aluminium, mild steel, stainless steel, cast iron, and much more. In addition, there are a variety of different welding processes and situations where welding may be used. Therefore, you can specialize in one welding technique or metal or get qualified in a variety of different techniques and metals.

Some of the common responsibilities of a welder could include:

- Ensuring that each project is completed safely and in a durable way for continued use.

- Following all safety procedures required while completing their job.

- Ensuring that each weld is completed to engineer/industry/trade standards.

- Assembly and fabrication of individual components.

- Assembly, cleaning, and storage of cleaning equipment.

How To Become a Welder in Six Steps

Follow the steps below if you are interested in pursuing a career as a welder:

- Identify The Different Types of Welding Jobs Available to You

- Take the Appropriate Welding Courses

- Earn Your Welding Certificate

- Gain Hands-On Welding Experience

- Become A Certified Welder

- Begin Your Job Search

1. Identify The Different Types of Welding Jobs Available to You

When it comes to welding, you have a variety of different choices. While some jobs, such as boilermaker welder, may be able to do multiple jobs, others, such as a shipyard welder or rig welder, maybe more industry-specific.

It’s important to note that different countries have different names for welder and their appropriate trade or qualifications. So, if you’re considering becoming a welder, always research what is required in your country or the country you intend on working in.

Below, we’ll take a look at some of the more common types of welding jobs:

- Construction Welders

- Manufacturing Welders

- Structural Steel Welders

- Sheet Metal Workers

- Boilermakers

- Industrial Maintenance Welders

- Industrial Shutdown Welders

- Rig Welders

- Pipefitters

- Motorsports Welders

- Shipyard Welders

- Military Welders

- Underwater Welders

Once you have identified what type of welding you’re interested in, you can then research what courses, experience, and qualifications are required to obtain that job. It’s also a good idea to check the salary and the demand for the job. After all, it’s no use becoming a shipyard welder if there are no shipyards near you and you aren’t willing to relocate.

While some of these jobs sound amazing, such as underwater welders, it’s important to note that only a small percentage of welders will ever make it this far. Underwater welding, for example, requires a huge amount of experience and qualifications, and even then, it can be extremely difficult to break into the industry.

Always be realistic about what type of welding job you are looking for and how hard you’re willing to work to get into that industry or role.

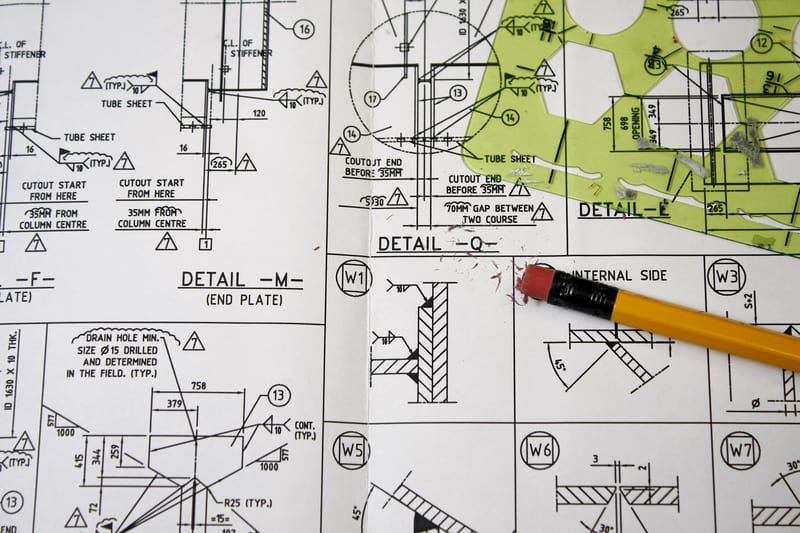

2. Take the Appropriate Welding Courses

Once you know what type of welding career you want, it’s time to do some research. First, you’ll need to identify what welding courses are required. Most welding courses require a basic high school education. Some employees are willing to pay for you to complete training courses, but others will require you to have them completed prior to applying.

If your high school offers any welding or fabrication courses, then it’s always a good idea to take advantage of them while you can before entering the workforce.

If you have a preferred welding career in mind, start to investigate which courses you need, if you can complete them on your own, and how long they are going to take. Also, look at how much welding experience you’ll need to have before you move into a specific field.

3. Earn Your Welding Certificate

Once you know what courses you need to take and how and when to take them, it’s time to get organized and get them done. Most welding courses last anywhere from six months to twelve months and can be either full-time or part-time welding courses.

Many welders take advantage of part-time or night courses to complete further education. In addition, some welding companies actively encourage their employees to get further education, and you may be able to get some courses done before you work. However, most companies require a minimum of certain certificates to be completed before you begin work.

It’s always a challenge to get experience in welding and complete welding certificates without having a job in the welding industry, resulting in a catch 22 where employers want these things. Still, they’re hard to get without having a job first.

4. Gain Hands-On Welding Experience

Gaining hands-on experience could mean starting as a trade assistant or laborer before working your way into a position as an apprentice. Many employees choose apprentices from existing labor as apprenticeships require a specific time commitment.

As an apprentice or trade assistant, you will complete basic welding jobs, work alongside qualified tradespeople to learn the trade, and gain valuable experience in the welding industry. While completing this on-the-job training, you will also be learning at trade school about different metals, welding techniques, and industry-specific processes.

Your time as an apprentice is what you make of it and what you put into it. The more hard work and commitment you put into being an apprentice, the more valuable information you’ll learn. At the end of your apprenticeship, you may become a qualified welder in your field, but there is still a lot more to learn.

As an apprentice, you usually rotate around the worksite and work with a variety of different tradespeople, completing different roles. This can provide you with a vast amount of experience competing different tasks and learning from different teachers. Thus, the apprenticeship system is a valuable and traditional way to learn a trade.

5. Become A Certified Welder

Some countries require you to complete an exam once you have finished your trade time, and others do not. Once you have completed your time as an apprentice and completed your trade examination if required, you are signed off as a qualified trade welder and now able to work as a full-time welder.

Many companies would employ their apprentices to continue with the company if they had a satisfactory apprenticeship experience. However, others are happy to train apprentices as they are a cheaper labor force. Once completed, apprentices may need to look for full-time work in another company or location.

However, as a qualified welder with four or more years of trade experience in your industry, you are now in a much better position to secure yourself a better job. Take the time to join a local union if there is one, as they may be able to help you secure long-term welding work or point you in the direction of employers that are searching for new employees.

6. Begin Your Job Search

If you do need to secure another welding job, you’ll already be in a much better position than you were several years ago. This is because you now have your basic qualifications, years of on-the-job experience, and even certifications to back up your on-the-job skills.

Along with the necessary paperwork and on-the-job experience, you also know what you are getting yourself into. While TIG welding racecar exhausts look great on social media, the reality of the welding industry is a lot different.

For most people, their welding career will find them in some of the most uncomfortable, dirty, cramped, hot, and unventilated locations in the world. You will end up working long hours, for many days at a time, in some of the most remote locations in the world, away from friends and family, sometimes for weeks or months at a time.

However, the job generally pays well, and the harder the welding, the more money you will earn. It’s a great trade to get into if you’re not afraid of a little hard work and not afraid to get your hands dirty. In addition, there is such a wide selection of different areas to specialize in that welding offers you a wide variety of different career choices.

One Welder’s Personal Story

After I left school at 16, I was a little lost about what to do. I wasn’t afraid to get my hands dirty and knew that a trade would be good, but I needed a little push.

Not one to waste any time, my father enrolled me in a pre-vocational aluminium welding course. The course lasted six months, and after that, I would have completed the theory component of my first apprenticeship year.

In Australia, you do approximately four years as an apprentice while employed by a company to complete your trade qualification. These four years involve a certain amount of time at trade school (TAFE) and a lot of on-the-job training. At the end of four years, you have your trade certificate if you complete all the components, and you are signed off by TAFE and your employer.

I was lucky that a large aluminium shipbuilder was located close to where I lived. I completed by trade welding aluminium and spent the next few years working there at the highest level, conducting regular x-ray quality welds, before being laid off due to a slow down in the industry worldwide.

After that, I did some shutdown work for manufacturing and mining companies. I would arrive on-site for anywhere from two weeks to two months, work with a crew of people welding different components, different shifts, and lots of long hours. You didn’t always know what you would be doing, but the money was great.

During this time, I secured several years of work welding a large private contract for a millionaire in another state. After that, I did almost two years of FIFO (fly-in-fly-out work) before returning to my original employer for another six years.

After spending almost fifteen years as a welder, I decided to transition into another industry job, WH&S (workplace health and safety). As a WH&S rep, I needed to complete another year of further education, but my industry and trade experience proved invaluable for my career choice.

Welding has allowed me to travel across my country, around the world, working in various industries from shipbuilding to mining and even manufacturing. I have accumulated various qualifications and worked with hundreds of different projects. Welding is also a great stepping stone into other industry-related jobs.

I may not be welding now, but I can still pick up a welder and repair a car trailer or boat for a friend and even work at home on my own projects. I’m confident welding with a MIG, TIG, or stick welder and can weld stainless steel, aluminium, and mild steel if I need to. As part of my apprenticeship, I also spent a lot of time fabricating different components and even did some basic fitting and turning, fit-out, and construction work.

So to sum it up: If you enjoy working with your hands, take pride in your work, and have an eye for detail, then welding could be the perfect career choice for you too.