“This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.”

MIG welding is one of the most popular welding methods that exist. Considered one of the easiest welding methods to learn, there are two types of MIG welding: gas and gasless. There are many similarities between the two, along with specific advantages and disadvantages to each.

Gasless MIG welders (aka self-shielding flux core) are capable of welding thicker metal than gas MIG welders, including metal that has rust, dirt, paint, etc. They are more portable, have higher productivity, and can be used outdoors or in windy conditions without contaminating the weld pool.

In this article, we look at the pros and cons of gasless MIG welders and how they compare to gas MIG welders. To learn more about the capabilities and efficiency of gasless MIG welders, how gasless MIG welders measure up compared to gas MIG welders, and how well multi-purpose MIG welders work, keep reading.

What is the Difference Between Gas and Gasless MIG Welding?

There are some key factors that separate gas MIG welders from gasless MIG welders. Both use the MIG, or metal inert gas, welding method. Due to the nature of MIG welding, a shielding substance is needed to prevent corruption, which is where the main difference between gas and gasless MIG welding comes into play.

- Gas MIG welding (aka GMAW, or gas metal arc welding) uses shielding gas from a tank or cylinder that is fed through the welding gun along with a wire to protect the weld.

- Gasless MIG welding (aka FCAW, or flux core arc welding) uses a self-shielding flux core wire instead of shielding gas during the welding process.

Gas and gasless MIG welders are capable of different things, such as where they can be used and what type and thickness of metal they are able to weld. The different aspects of gas and gasless MIG welding can get complicated and often technical, so we have broken them down into categories to better compare the two.

Use of Shielding Gas

Here’s the thing about gasless MIG welders – they are not technically gasless. They just use a self-shielding, flux core wire that produces vapors (aka, gas) that protect the weld pool from contamination. The vapors also create slag that provides additional protection from contamination, though it does need to be cleaned after welding.

By comparison, gas MIG welders use a shielding gas from a tank or cylinder to prevent contamination of the weld pool. This gas is fed to the welding gun through a hose from the welding machine. When the trigger is pressed, both the wire and the gas are fed from the nozzle to heat and fuse the metal being welded.

Fumes

One key difference between gas and gasless MIG welders is the amount of smoke and fumes that are produced during the welding process. With gasless MIG welding, more smoke and fumes are produced than with gas MIG welding, which produces little to no smoke.

The fumes produced during gasless MIG welding contain toxic chemicals that can cause serious health damage. Exposure to these fumes can lead to short-term effects including dizziness and nausea, and prolonged exposure can cause cancer. Because of this, gasless MIG welding should only be done outdoors or in a well-ventilated area.

Indoor and Outdoor Suitability

The flux core wire in gasless MIG welders uses compounds that produce a protective vapor during welding. This makes gasless MIG welders more stable and better suited for outdoor use, as they are not vulnerable to contamination from wind that causes weaker, lower-quality welds.

Gas MIG welders, on the other hand, can usually only be used in an indoor area that is free from wind or drafts. The shielding gas that is used in gas MIG welding is a protective component, but it is more susceptible to contamination from wind or outdoor elements.

If a gas MIG welder is used in a windy or drafty area, the shielding gas could be pushed away from the welding pool by the wind, causing a lower-quality weld that can contain air bubbles and imperfections. The result is a weaker, lower-quality weld that is not as long-lasting.

Metal Preparation

In gas MIG welding, it is important that the metal to be welded is clean and free of any rust, dirt, paint, or other debris. This is not the case with gasless MIG welding – the flux core wire enables welding even on metal that has rust, paint, or other debris, alterations, or imperfections.

This reduces the cleaning and preparation time for gasless MIG welding, though it is recommended that you still clean the metal before flux core welding for better results. It does make gasless MIG welding slightly more convenient, as the metal does not have to be perfect before the welding process can begin.

Welding Capabilities

One difference between gas and gasless MIG welding is not in the welding process itself, but rather the specific type and thickness of the metal that can be welded with each method.

Gas MIG welders can weld:

- Stainless and mild steel, aluminum

- Metal that is 24 gauge (less than 1/16″) up to ½”

- Clean, smooth metal that is free of rust, dirt, paint, and other debris

Gasless MIG welders can weld:

- Stainless and mild steel

- Metal that is 20 gauge (about 1/16″) up to 1″

- Metal that contains rust, dirt, paint, or other debris

It should be noted that with gas MIG welders, the thickness of metal that can be welded depends on the materials used and the type of welder. Most non-industrial gas MIG welders are capable of welding metal up to ¼” thick.

On the other hand, gasless MIG welders have better penetration, making them much more suitable for welding thicker metal with good results. They are also more efficient and have higher productivity than gas MIG welders.

Multi-Purpose MIG Welders

Some welders are multi-purpose, meaning they can be used for gas or gasless MIG welding. This provides the benefits and capabilities of both welding methods without the need for multiple machines, making 2-in-1 welders an appealing option for a wider range of projects and uses.

It should be noted that gas and gasless MIG welding processes require different materials, so some knowledge of the equipment and settings used with each method is needed to change from one to the other.

Type of Wire

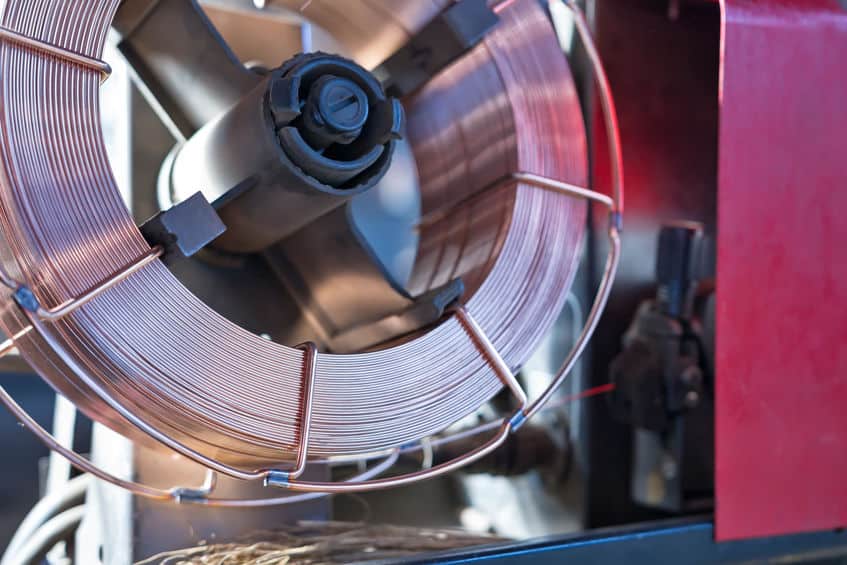

All MIG welders use a wire that is fed to the welding gun from a spool in the welding machine. The wire acts as an electrode in the welding process to heat, melt, and join two metals. Gas MIG welders use a solid wire which is fed simultaneously along with shielding gas from a tank or cylinder through the welding gun.

By comparison, gasless MIG welders use a hollow, self-shielding flux core wire. As the wire is burned during the welding process, a gas is formed that protects the weld pool. There are various sizes and types of welding wires that are used for different purposes – generally, welding thicker metal requires a thicker welding wire.

Polarity

Gas and gasless MIG welders use different polarity settings during the welding process, which is one of the most significant factors that sets the two apart. Using the correct setting and wire for each method is very important, and if you are using a multi-purpose welder, you will need to know the difference:

- Gas MIG welders use a DCEN (direct current electrode negative) setting

- Gasless MIG welders use a DCEP (direct current electrode positive) setting

Basically, in gasless MIG welding, the torch polarity must be set to negative (-). In gas MIG welding, positive torch polarity is needed. Many multi-purpose welders have settings to change the polarity which are described in the manual, depending on the capability of the welder.

Appearance and Cleanup

With gas MIG welding, the final weld is usually very neat and clean, produces little to no spatter, and does not require sanding or chipping. This reduces the amount of cleanup time after welding. Gasless MIG welding produces more spatter as well as slag, which must be cleaned after the metal has cooled.

Pros and Cons of Gasless MIG Welders

As with all welding methods, gasless MIG welding has advantages and disadvantages to consider when determining if it is a good option. For welding thicker metal that contains dirt, rust, paint, etc., gasless MIG welding is a good option. If you want to weld thin metal, aluminum, or perform auto body work, gas MIG welding is better.

Some of the pros of gasless MIG welders include:

- Can be used outdoors or in windy conditions

- Portable – use less equipment than gas MIG welders

- Welds metal that has dirt, rust, paint, or other debris

- Good penetration makes for easy welding of thicker metal

- Can be used in all positions (with proper filler material)

- High productivity and deposition rate

Cons of gasless MIG welders include:

- Produce more fumes than gas MIG welders

- Produce spatter and slag that must be cleaned

- Not very suitable for welding thin metals

- Difficult for vertical and overhead positions

Gas vs Gasless MIG Welders: Which is Better?

When it comes to deciding between a gas or gasless MIG welder, which is the better option depends on a number of things. Both produce strong welds, are among the easier welding methods to learn and use, and are suitable for home or hobby welding as well as industrial welding.

Some factors to consider when choosing between a gas and gasless MIG welder include:

- Thickness of the metal to be welded – gas MIG welders are good for thinner metals, including sheet metal; gasless MIG welders can weld thicker metal more quickly and effectively

- Type of metal to be welded – gasless MIG welders are mostly used on steel, whereas gas MIG welders can weld steel, aluminum, and some other metals

- Where the welding will take place – gas MIG welding is best (and usually recommended) for indoors, while gasless MIG welding is more suitable for outdoors

- Skill level of the person doing the welding – gasless MIG welders tend to be easier for beginners

- Cost – gasless MIG welding requires fewer materials and is considered to be less expensive than gas MIG welding overall due to its higher productivity

- Appearance – gas MIG welders produce little to no spatter, no slag, and are not as likely to cause burn through on the metal

- Portability – gasless MIG welders do not require a shielding gas tank or cylinder, making them lighter and more portable than gas MIG welders

- What it will be used for – gasless MIG welding is good for repairs, manufacturing,

Many welders are capable of both gas and gasless MIG welding, so if you are not sure which will best meet your needs, a multi-purpose (gas and gasless) welder provides the best of both worlds. However, a gas and gasless MIG welder will likely be heavier and therefore less portable than a gasless MIG welder.

What is the Best Gasless MIG Welder?

The quality, capabilities, and cost of welders vary, and it can be difficult to determine the overall best welder. However, some are more suited for different purposes and skill levels. Someone who has less experience with welding will likely benefit more from a different welder than someone who has been welding for years.

There are numerous gasless MIG welders available – choosing which is best for you will ultimately come down to your personal needs and preferences. Key factors to consider before investing in a gasless MIG welder are: your skill level and experience, where you plan to weld, what your budget is, and what projects you plan to do.

Best Gasless MIG Welders for Beginners

Aside from proper training and knowledge, choosing the right welding equipment is one of the most important steps for those who are interested in learning how to weld. For beginners, a basic welder that is easy to use is recommended. However, it is also important to find a quality welder that will get the job done without breaking down.

Some of the best rated and most recommended gasless MIG welders for beginners are:

| Welder | Type | Voltage &Output | Weight | Features | Cost |

| Etosha MIG 140 Welder | Flux core wire, gasless | 110V, 140 amp | 14.77 lbs | Welds steel up to ¼” thick, simple controls/ settings, IGBT inverter, electric choke control, safety protections, portable | $141 |

| Goplus No Gas 130 MIG Welder | Flux core wire, gasless | 110-120V, 30-120 amp | 15.5 lbs | Safety protections, synergic adjustment function for voltage/wire feeder speed, IGBT inverter, capable of over 85% efficiency, portable | $140 |

| Vivohome Portable Flux Core Wire No Gas MIG 130 Welder | Flux core wire, gasless | 110V, 50-120 amp | 37.2 lbs | Welds thin steel, aluminum, and thick steel; 4 levels of current flow settings, 10 welding speeds, variable feed control, portable | $150 |

| Lincoln Electric K2278-1 Handy Core | Flux core wire, gasless | 115V, 35-88 amp | 45 lbs | Welds mild steel 18 gauge to ⅛”, can be used with household outlets (115V, 20 amp), easy setup and use, portable | $279 |

| Forney Easy Weld 261, 140 FC-i Welder | Flux core wire, gasless | 120V, 140 amp | 19 lbs | Welds mild steel up to ¼” thick, simple wire speed control, easy to set up and use, portable | $227 |

All of the welders listed above are good options for those new to welding, as they are meant for home use, do-it-yourself projects, and small maintenance and repair projects. They are on the less expensive side, are portable and fairly easy to use, and make great first welders for beginners and those who are learning a new welding method.

Best Multi-Use Gasless MIG Welders

If you already have experience with MIG welding and are looking for a good gasless MIG welder for more advanced jobs, there are several options available. These tend to be a little more expensive, but they also offer additional features that allow for different types of welding, advanced controls and settings, and other advantages.

Some of the best gasless MIG welders based on user ratings and reviews include:

| Welder | Type | Voltage & Output | Duty Cycle | Weight | Weldable Materials | Features | Cost |

| Hobart Handler 140 MIG Welder | MIG, flux core | 110/115/120V, 25-140 amp | 20% | 57 lbs | Steel, stainless steel, aluminum | 5-position voltage control selector, welds mild steel 24 gauge to ¼” | $680 |

| Lincoln Electric Power MIG 210 Mp K3963-1 | MIG, flux core, DC stick, DC tig | 120/230V, 20-140 amp (120V), 20-220 amp (230V) | 40% (120V), 25% (230V) | 40 lbs | Steel, stainless steel, aluminum | Digital controls, color display, advanced options & settings, easy to use, suitable for TIG and stick welders | $1,800 |

| Forney 318 190-Amp MIG Welder | MIG, flux core | 230V, 35-190 amp | 25% | 63 lbs | Steel, stainless steel, aluminum, cast iron | Cast aluminum wire drive system, welds heavy duty materials, easy to use, welds 24 gauge to ⅜” | $754 |

| Lotos MIG 175-Amp Welder | MIG, flux core | 200-240V, 30-175 amp | 20% (175A), 30% (135A) | 85 lbs. | Steel, stainless steel, aluminum | Aluminum wire feeder, multi-use, durable, easy setup, welds steel 18 gauge-¼” and aluminum up to 3/16″, includes spool gun | $521 |

Conclusion

Gasless MIG welders have several advantages – they produce strong, high-quality welds, are great for repairs, manufacturing, and welding thicker metals, and are more portable and convenient than gas MIG welders. They are becoming more widely used due to their high productivity, efficiency, and overall lower equipment cost.

Welding thin metals is not recommended with gasless MIG welders due to their increased penetration, and they are slightly limited in the type of metal that can be welded. However, the portability of gasless MIG welding along with its ability to be performed in windy conditions is ideal for outdoor repairs, especially in agriculture.

Sources

Gasless Mig Welder Vs Gas Mig Welder | uwelding.com.au

Gasless MIG Welding | atlanticaspiration.com

The Difference Between Gas and Gasless Mig Welding | welderstation.com

Gas Vs Gasless Mig Welder Pros and Cons | inspiringhomestyle.com

GMAW: GMAW vs FCAW-S Process Comparison | lincolnelectric.com

MIG Welding: The Basics for Mild Steel | millerwelds.com

Uses and Advantages of Flux Core Arc Welding | tws.edu

Solid Wire Versus Flux-Cored Wire: When to Use Them and Why | millerwelds.com

Flux Core Welding vs. MIG Welding – The Main Difference Explained | weldinginsider.com

Difference Gas Gasless Mig Welding | welding-hq.com

No Gas Mig Welders | BestReviews.Guide

Best MIG Welders [110V & 220V] Reviews | Weldingpros.net

Flux-Cored Wire Versus Solid Wire | Keen Ovens (keenovens.com)