“This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.”

MIG welds are the most commonly used welding style by those that are fabricating or repairing items at home. The process seems simple enough, which is why it is so frustrating when the MIG weld comes out wrong.

There are four main reasons why your MIG weld looks bad after you have completed the job. They are porosity, lack of fusion, burn through, and crater cracks. Knowing what you are doing when you are making the MIG weld will help prevent errors in the fabrication process.

In any case, learning exactly what the issue is that is causing the MIG weld to look wrong needs to be fixed to fabricate or repair the item properly. Knowing some of the major causes of improper MIG welds and how to prevent them is key to a successful job.

Porosity

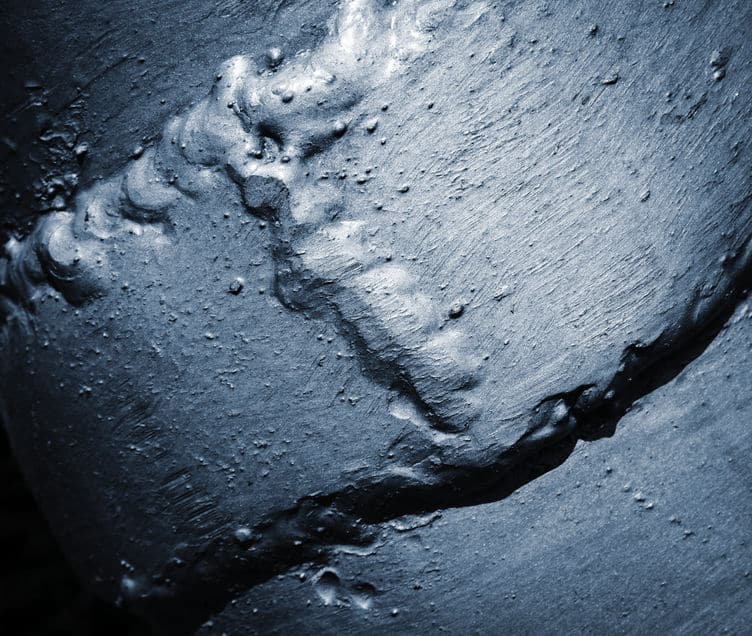

Porosity is one of the four reasons MIG welds come out looking bad. Porosity is best described as tiny holes that develop in the material you are welding. The tiny holes that are created cause a space in which air and water can penetrate the weld, weakening the material. Porosity is not only unsightly, it can cause your weld to eventually fail.

Porosity is something that can generally be prevented as long as the welder takes certain steps to avoid the common causes. Porosity can be caused by a few different things, such as improper gas shielding, surface contamination, lack of gas supply, high winds, presence of water, and filler metal contamination.

Improper Gas Shielding

This type of issue is caused when the gases used in the MIG welding process do not dissipate correctly. This can occur when the weld pool is exposed to the air and atmosphere which causes the weld to become contaminated by those gases.

When the weld pool is exposed unnecessarily, the gases get trapped inside the weld pool which in turn creates tiny holes on the face of the weld or its interior. Any gaps in the weld could lead to instability and failure in the future.

Improper gas shielding is caused by several factors:

● Incorrect equipment settings

● Holes present in the weld

● Excessive exposure to winds

In order to prevent this type of situation from occurring, the MIG welder should ensure that the area in which they are welding is free from any type of high winds, dust, or other contaminants that can get into the weld. Additionally, the MIG welder should be inspected before use to ensure that there are no failures of the equipment that will lead to damage.

Surface Contamination

Another issue that causes unsightly MIG welds is contaminants being present on the material you are welding. Any chemicals that are present on the material (oil, gas, etc.), will cause the weld to develop wormholes. A wormhole, in the welding world, is gas that has been trapped inside of the weld pool as it is solidifying.

Wormholes are noticeable because they create long pores throughout the bead as gas is trapped while the weld metal is solidifying. To avoid wormholes, make sure that you have completely cleaned any surface on which you are going to weld. If there are any signs of heavy paint or primer, make sure to clean the area before beginning to weld.

Lack of Gas Supply

Another cause of porosity in your MIG welds is if there is an interruption in the supply of gas to your equipment. Interruption of gas will prevent you from properly creating the weld pool which will ultimately lead to porosity. Lack of gas supply can come from several different things:

● Running out of gas

● Obstruction in the gas line

● Equipment failure

Always check the amount of gas in the cylinder that you are using before you begin welding. If the cylinder is low on gas, it will cause intermittent disruptions in the heat created by your welder.

If the cylinder appears to have enough gas in it or you have replaced the cylinder and are still noticing an issue, inspect your equipment to ensure that there is no debris that could be causing the fuel from not getting where it needs to go.

High Winds

Believe it or not, high winds can also affect the quality of your MIG weld. Strong gusts of air caused by a fan or from the elements outside can cause the weld to be blown off of its intended target.

When you are going to work on your MIG weld, make sure that you do so in a manner to prevent any high winds from impacting the job. If a fan is a culprit, either shut it off while you are welding or position it in a manner so that it does not blow in the direction of the weld.

If the wind source is due to the weather outside, consider moving your work inside of an open garage to shield yourself and the weld from the high wind. Taking a few moments to ensure that any amount of heavy winds does not damage your weld will save you headaches in the future.

Water

Any type of liquid that may be present on the material that you are MIG welding can also interfere and cause porosity. If there is water that is present on the material, the weld pool will not solidify properly.

If you have cleaned the item you are welding with water or another liquid before doing the job, dry it completely with a towel or wipe cloth to ensure that it is free from any moisture. Take special care when inspecting the item after you have dried it off. Ensure that no other type of debris is present before you start to weld.

Filler Metal Contaminated

Sometimes you may notice porosity on your MIG weld but you have ruled everything else out as a possible source. Take time to inspect the filler metal that you are using to create the weld pool. Filler metal, like anything, can become contaminated over time. This is especially true when it is kept in the garage where it can degrade over time.

Filler material could be contaminated by:

● Rust

● Dirt

● Debris

Filler metal could have some type of contaminants or debris present which will affect the weld. Additionally, rust or other forms of corrosion could be present. This is especially true if the filler metal has been stored in an area prone to moisture.

You might inspect your filler metal and find no obvious issues. However, if you have ruled everything else out, replacing your filler metal is a safe option. The cost of the filler metal is well worth preventing any future headache caused by welding with faulty material.

Lack of Fusion

If porosity does not seem to be the likely cause of your MIG weld looking bad, then perhaps it is a lack of fusion. When the weld pool is not fusing properly with the material you are welding it is considered a lack of fusion.

If you are experiencing a lack of fusion with your welding material, there are some likely culprits which you need to rule out. They are an improper heat supply, bead not being properly aligned, welding material not lined up properly, or imperfections on the welding surface.

Improper Heat Supply

Welding requires a high degree of heat to melt the metal filler material that is being used to create the weld. If the heat being produced by your equipment is insufficient to create the proper temperature to melt the filler metal, a proper bead cannot be created.

Typically, the cause for this type of issue is human error. If the temperature setting is not correct, the filler metal will not melt properly. Inspect the packaging the filler metal came in to ascertain what temperature is needed to properly create the weld pool.

If, after any adjustments, the heat is still not sufficient, you may have a problem with your equipment. Inspect the equipment to determine if there are any failures that can be noted. Make any possible repairs. If the equipment cannot be repaired, you will have to get different equipment to complete the weld.

Welding Material not Lined Up Properly

Another common issue that causes a lack of fusion is when the welding material is not lined up properly at the edges of what you are welding. Follow the steps below to be sure that your welding material is properly aligned.

● Ensure material is line up properly with the edges

● Check material for debris

● Use proper cleaning practices

To get a proper weld, line up the material with the edges before continuing with the MIG weld. If this does not seem to be the issue, then make sure that you have checked the material for any type of debris that you may not have noticed before. Debris can get in the way, preventing the materials from lining up properly

Inspect the surface to ensure there are no areas that need to be cleaned before continuing the job. If you utilize a cloth or other cleaning object to clean the material’s surface, make sure that there is no lint or anything else that is left behind.

Bead not Properly Aligned

Anyone who has been welding for any length of time should know that the bead needs to be lined up at the welding point. However, even the best welder sometimes makes simple mistakes. Not having the bead lined up properly at the welding point can also cause a lack of fusion.

The lack of fusion, in this instance, occurs because the area in question cannot be properly sealed. The weld pool does not properly seal off any open areas which will cause the weld to fail in the future.

Take time to ensure that your bead is aligned properly at the welding point before continuing your work. Taking time to ensure that the job is completed properly the first time will save you the hassle of repeating your work in the future.

Surface Imperfections

If you have determined that your MIG weld looks bad due to a lack of fusion, and you have checked all other plausible reasons for the issue, inspect the material you are welding. Occasionally, the material that you are working on may have imperfections that are preventing a proper weld.

A surface imperfection can be something as simple as a small scratch in the material to something obvious like the presence of burrs. Do not simply try to weld over the imperfection as this could cause a lack of fusion. Rather, attempt to repair the issue if it is possible.

In some cases, it may not be possible to repair the material that you are welding properly. If this is the case, it is suggested that you scrap what you have and get new material in order to get the job done correctly.

Burn Through

Another reason your MIG weld might look terrible is because you may have inadvertently burned through the material. This is known as burn through. Burn through typically occurs for the following reasons:

● Heat output is too high

● Movement is too slow

When this happens, the heat from the equipment will cause warping, or literally burn through what you are welding. Any burn-through of the material you are welding will cause it to be structurally unsound and cause potential problems in the future.

Adjust the settings on your equipment to the lowest heat possible to melt your filler metal. If there is still an issue with burn through or warping, adjust the speed at which you are welding.

If speed is the issue, only make minor adjustments until you find the right speed. Going too slow will damage the material while going too fast will prevent a proper weld.

Crater Cracks in the Material

Crater cracks are common when MIG welding aluminum because of its composition. When aluminum is being MIG welded, the volume of the material is reduced by 6% while hardening. This automatically creates a void that must be filled. When the metal filler is not sufficient to fill the void left over after the aluminum, a crater crack forms.

Preventing Crater Cracks

Crater cracks typically happen when the welder takes their finger off of the trigger at the end of the MIG weld. The best way to prevent this type of crack from happening is to end on an existing weld.

Stopping the weld on an area already done is known as a backstep. Backstepping is when you take to reverse the direction of your weld, going toward the area where the weld has been completed.

Go over the existing weld for roughly half an inch beyond the crater crack and then release the trigger on your equipment. By doing this, you are completing the weld as well as ensuring that a crater crack is not going to occur in the aluminum.

Repairing Crater Cracks

Crater cracks weaken the strength of the weld and will lead to failure if left without repair. Additionally, the crack can extend down the centerline of the weld which will make the weld more unstable.

Repair of the crater crack must be done as soon as it is noticed to prevent further damage to the material you are MIG welding. To repair the crater crack, the welder must use metal filler over the area until the crack has been filled.

To prevent further cracking, the welder should back step back to the previous weld and end the project at that point. As stated above, the welder needs only to back step approximately half an inch before stopping the weld.

Inspection of Weld

Even the most seasoned MIG welder is prone to make a mistake every now and then and cause damage to the project on which he or she is welding. The proper time and care must be put in to ensure that the weld is fused properly and that no other damage was done during the welding process.

Not all MIG weld damage can be seen on an initial inspection. Damage can occur to the material that you have MIG welded even if everything looks appropriate at first glance. However, improper sealing or other issues that were missed during the initial work will cause issues and possible failures in the future.

Taking these steps to inspect your finished MIG weld can help ensure that it is stable and has lasting integrity. Doing so can help prevent damage down the road.

● Make sure the weld beads completely cover any potential gaps

● Check to ensure the weld is holding if under pressure

● See that no portion of the weld will lead to leakage in the future

Final Thoughts

MIG welding is one of the most popular methods for do-it-yourself welders, as opposed to going to a repair or fabrication shop. Those who take the time to learn the craft take pride in their work and want to ensure that their welds are successful and last for a long time.

Ensuring that you are aware of the four common issues that could make your MIG welds look bad will help you avoid them, saving you frustration and time in the future.

Sources:

MIG Welding Troubleshooting – Common Problems And Solutions | welderportal.com

The Most Common MIG Weld Defects on Aluminum and Steel and How to Avoid Them | millerwelds.com

Porosity in MIG Welding – How Should a Good Weld Really Look Like | weldingmania.com

MIG Welding: The Basics for Mild Steel | millerwelds.com

Porsoity Inwelding | weldsmartly.com

What Are Wormholes and How Can They Be Prevented? | twi-global.com

Trouble Shooting for Aluminum Welding | alcotec.com

Welding Aluminum | mewelding.com

2 thoughts on “Four Reasons Why Your MIG Weld Look Bad”