“This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.”

Among welders, there is a lot of argument over whether inverter welders or oil-cooled welders (also known as transformer welders) offer the better option for performing a welding operation. Everybody has a favorite, and both are good options that offer their own set of benefits and drawbacks.

So out of inverter welders and oil-cooled welders, which is the better welder? The answer is that while inverter welders used to be much more expensive and unreliable than the oil-cooled welders that came before them, inverter welders have since closed the gap and are considered more reliable and articulate than oil-cooled welders.

Oil-cooled welders are a solid bit of technology, but the inverter welders that followed them introduced a new level of technology to the welding craft that allowed for a much more intricate weld. Read on to find out more about these two different kinds of welders.

What Is an Oil-Cooled Welder?

Oil-cooled welders are an older form of welding technology that dates back to the beginning of welding, which was invented in the late 1880s. These types of welders have been made for decades, and many older ones are still in service today.

Since its earliest beginnings with oil-cooled transformer-based welders, welding has branched off into several major branches, including the following:

- Submerged arc welding

- Gas tungsten arc welding (TIG)

- Gas metal arc welding (MIG)

- Flux-cored arc welding

- Plasma arc welding

- Electroslag welding

- Electrogas welding

While the craft of welding has made many technological advancements over the course of the twentieth century, oil-cooled welders were used for the majority of it, and it wasn’t until the advent of computers in the eighties and nineties that welders began turning to inverters.

Still, the reason that oil-cooled welders are still around is that the initial technology is still sound, and these machines are still capable of producing very efficient and heavy-duty welds in all kinds of conditions.

Advantages of Oil-Cooled Welders

The inverter welder outperforms oil-cooled welder in many regards, but there are some benefits to using an oil-cooled welder, especially when it comes to performing heavy duty welding operations. Here are some of the advantages of oil-cooled welders:

- Reliable: Oil-cooled welders are widely considered to be reliable machines, and many that were created decades ago are still in active service today. When it comes to such a large financial investment for a shop, reliability is a very important factor to consider.

- Durable: OIl-cooled welders are built to last and can work well, even in less than optimal welding conditions. Dirt and high moisture environments that will cause problems with other welders are conditions that an oil-cooled welder will take a licking and keep on ticking in, making them a good choice for rough on-location construction work.

- Higher duty cycle: Because the oil-cooled welder can tolerate a higher duty cycle, the oil-cooled welder can be used for longer stretches of time, allowing the welder to complete a job more quickly and efficiently with less downtime for cooldown.

- Tried and true: Because oil-cooled welders have been around for over a century, there have been plenty of refinements to the technology that have only served to make it more reliable and efficient. Many of the design flaws were ironed out of these welders decades ago.

Despite being the older form of welding technology, oil-cooled welding is still used in many industries today to perform welding operations in environments that would be considered unsuitable for inverter welders, and for longer periods.

Just because this welder is considered the granddaddy of modern welding machines doesn’t mean it’s time for it to go into retirement. But there are some significant drawbacks to oil-cooled welders as well.

Disadvantages of Oil-Cooled Welders

Oil-cooled welders may have some advantages, but they also have their share of drawbacks. Due to the fact that they are an older technology, there are many ways that they have been outperformed by newer welders.

Here are some of the negatives of owning an oil-cooled welder over an inverter welder:

- Less efficient: Oil-cooled welders aren’t nearly as electrically efficient as an inverter welder, which means that over time, an oil-cooled welder will cost much more in expended energy costs than an inverter welder would in its place.

- Oil is messy: Oil-cooled welders, especially older ones, can leak oil. This is especially an issue if the welder is being transported. Prior to the late 1970s, oil-cooled welders contained PCB-treated oil that has since been found to be carcinogenic. Most modern oil-cooled welders won’t have this issue, but for older models, it’s something to consider.

- Heavyweight: Oil-cooled welders are very heavy, and many older models do not even come with any kind of wheels or transport system, leading many mechanics to rig their own wheeled welder frames. This can make transporting an oil-cooled welder a hassle.

- Less arc precision: When it comes down to the weld, oil-cooled welders simply can’t weld with as much precision and adjustment as an inverter welder. This is fine since some welding jobs don’t require that level of fine-tuning, but it is something to consider when choosing between the two types of welders.

- Expensive: Most oil-cooled welders are priced in a range of several thousand dollars, and this is very expensive in comparison to the cost of inverter welders, which can be found for only a few hundred dollars.

What Is an Inverter Welder?

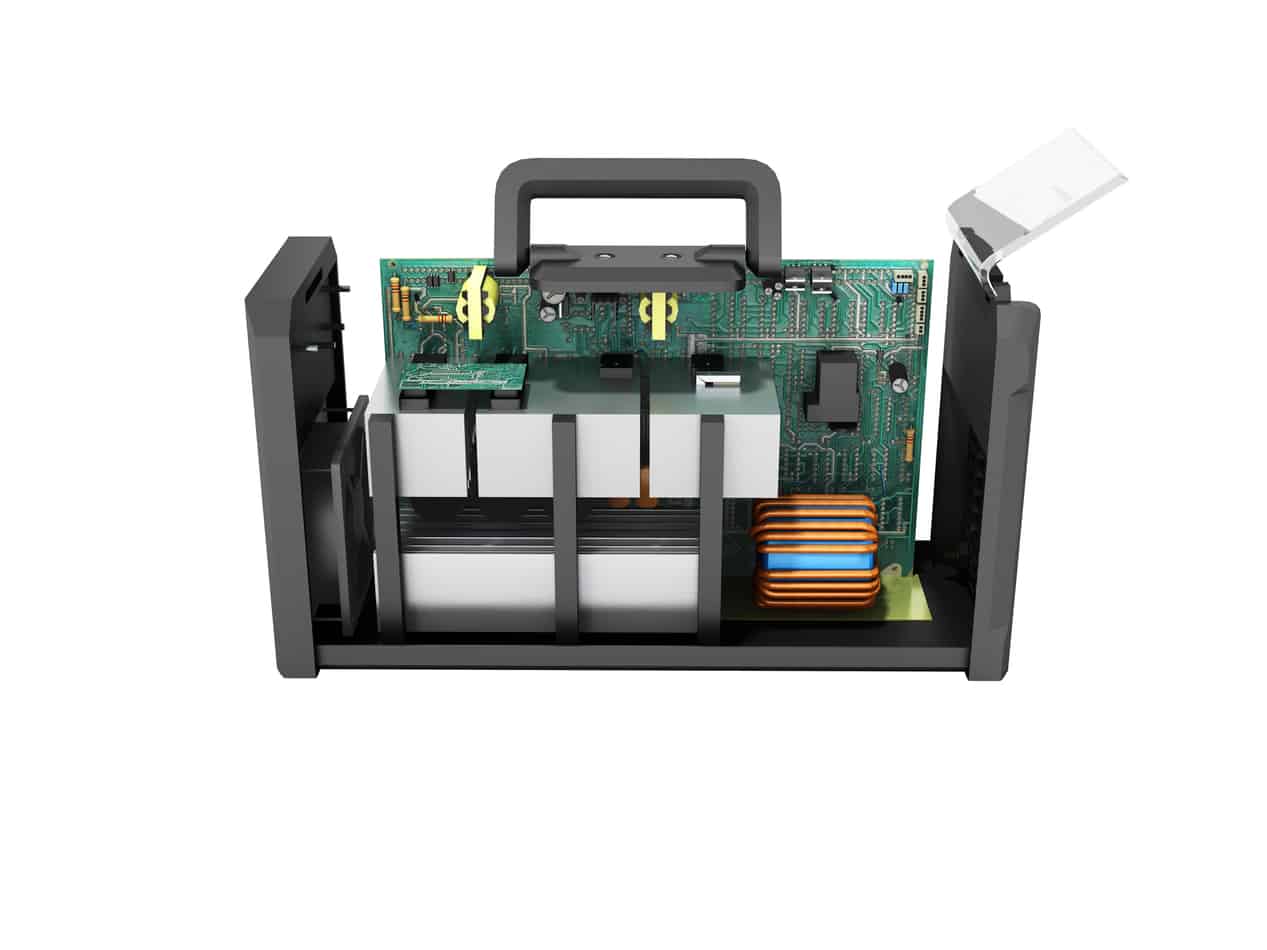

Inverter welders are a relatively new innovation in the welding industry and didn’t really take off until the 1980s, about a hundred years after the initial invention of arc welding.

Inverter welders really took advantage of the advent of computers in the 1990s, and within a few decades, inverter welders were capable of intricate welding settings that previous generations of welders could only dream of.

Inverter welders operate by transforming utility AC power into DC current at a high frequency that allows for electrical welding via a metal electrode. Tungsten is a popular choice. But by converting household electricity, inverter welders are able to wield a high degree of welding power even in a backyard or garage workshop

Advantages of Inverter Welders

Because they are an advancement on the older technology of oil-cooled welders, inverter welders feature several major benefits as they continue to revolutionize the art of welding. Here are some of the advantages provided by using an inverter welder:

- Precision work: By far, the biggest draw of inverter welders are their ability to do precise welds on a wide variety of materials, especially in conjunction with a TIG torch. An inverter welder can work on very thin materials as well as exotic metals.

- Small lightweight build: Compared to oil-cooled welders, inverter welders are much smaller and more lightweight, making them easier to transport to construction sites and other welding operations away from the workshop. These modern machines are often light enough to be carried around via a handle on the top.

- Voltage stability: Inverter welders are much more stable than their oil-cooled transformer counterparts, and this stability translates as a straighter, more even weld.

- Digital control: Most inverter welders have precise adjustment schemes that allow the welder to have very fine-tuned control over the welder’s arc and how much power it’s receiving. This can be vital for more intricate jobs where aesthetics are important for the result of the weld, or the welding materials are expensive.

- Lower operating costs: Inverter welders are much more energy efficient than their oil-cooled counterparts, and while they may be more expensive up front, they make up for this cost over the course of their working life with lower utility bills.

- TIG compatibility: Inverter welders are compatible with TIG torches, which are arguably the most versatile and high-quality welding torches available for any workshop. A TIG torch, in conjunction with an inverter welder, can tackle pretty much any job from automotive welding to intricate artwork.

Disadvantages of Inverter Welders

There are many benefits of inverter welders, but they do have their share of drawbacks as well. Here are some of the potentially negative aspects of owning an inverter welder:

- Older models considered unreliable: Back during the introduction of inverter welders in the late 1980s and throughout the 1990s, the technology was still very new, and these older models are not considered very reliable in comparison to oil-cooled welders, and experience more mechanical failure as a result.

Luckily in contemporary models of inverter welders manufactured in more recent years, this problem has been largely resolved, and the engineering flaws of earlier iterations have mostly been addressed and fixed. - Somewhat delicate in operation: Arc gouging and other incorrect welding procedures have the potential to damage the delicate electronics in an inverter welder, and repairing these kinds of problems is not cheap or easy. Inverter welders should be used by experienced welders who understand how to operate them correctly.

This concern is especially true of TIG welding with an inverter welding, as TIG welding is widely regarded as the most difficult form of welding to perform with any welder. - Less durable: While the small, lightweight design of most inverter welders makes them more portable and easier to transport, this lightweight design has also resulted in a less durable design as well.

There is also the issue of planned obsolescence, where the high-tech components of electronics are designed to become obsolete and require replacement over time. This means while a small inverter welder might cost less than an oil-cooled transformer, it will also be more prone to break down and need replacement faster.

How to Choose A Welder

When it comes down to choosing between purchasing an inverter welder or a traditional oil-cooled unit, it’s going to depend largely on individual preference. To determine which welder is the right choice, potential buyers should consider the following questions:

- What kind of welding do I require? As a general rule, oil-cooled welders are better suited for heavy duty work in rough conditions for long hours, whereas inverter welders are better suited for more precision-based welding work in clean indoor environments.

- What is my budget? How much money you have to spend on a welder will be a large factor in determining which type of welder to buy. Oil-cooled welders tend to cost thousands of dollars, while you can typically obtain an inverter welder for several hundred dollars instead.

- What kind of environment am I working in? Inverter welders have delicate electronic components that don’t work as well in high-moisture, high-dirt environments, and these air quality issues can cause cumulative damage to an inverter welder. Oil-cooled welders are a better option for dirty workspaces that may be exposed to water.

- What kind of welding torch do I want to use? If you are going to TIG weld, you’ll need an inverter welder to run it rather than an oil-cooled welder, but MIG and stick welding can be performed off of an oil-cooled welder just fine.

- How intricate is the welding I need to perform? Inverter welders are more stable and able to deliver a more precise arc, which makes them suitable for delicate welding work on easily damaged metal alloys. For rough plain mild steel welding, an oil-cooled unit will do the job just fine.

Where to Buy a Welder

There are many places that you can obtain either an inverter welder or an oil-cooled welder. Since most oil-cooled welders are older models, these are found most easily as used units on eBay and other digital marketplaces.

Inverter welders are easy to find from a variety of sources, and buyers have the option of either a used unit or a new unit. Since new inverter welders are relatively inexpensive and, older models are prone to reliability issues and digital hiccups, it is advisable that if you’re going to buy an inverter model, you go with the most recent model you can reasonably afford.

Whether you buy an inverter welder or an oil-cooled welder, you can also find units to buy at the following sources:

- Yard and estate sales: If you don’t mind waiting a bit to get a welder, you can scour yard sales and estate sales to see if you can snag a working welder in good condition.

Since welding is a relatively rare household hobby in comparison to many others, this can be a long game, but could eventually pay off with a decently priced welding unit for pennies on the dollar. Just make sure the unit is in working condition before purchase, or can at least be easily repaired. - Classified ads and Craigslist: Classified sections often have a section for the sale of machinery and equipment, and like yard sales, it is sometimes an option to get a cheaply priced welder used from one of these ads. The downside to purchasing anything used is the danger of an as-is purchase, though, and you won’t have a warranty.

- Tool supply stores: Stores like Harbor Freight carry welders and other tools and will allow you to actually see a physical unit in person before purchasing it. In case of a defective product or other issues, returning or replacing the item is usually less complicated in a physical store transaction as well.

- Tool supply websites: Many of the most popular welding brands, such as Lincoln Electric, Miller, and Eastwood have websites with catalogs of their welding equipment available for online purchase. As long as you don’t mind paying shipping cost (which may be expensive for a heavy welder) you can get a lot of options this way.

- Digital marketplaces: Digital department stores like Amazon offer what is probably the widest selection of different brands and types of welders, with extensive product descriptions and user reviews so you can get exactly what you need. The only downside is shipping cost and a possible hassle if you need to return or replace your welder.

No matter where you decide to buy a welder, be sure to note what kind of warranty you’re receiving with your purchase. One of the benefits of buying a new unit versus a used unit is that there is typically a multi-year warranty for either repair or replacement, and if you’re dropping hundreds of dollars on a welder, a warranty like that is nothing to sneeze at.

It’s also important to make sure you look at all the available options and consider them carefully, rather than making an impulse purchase. A welder is an expensive piece of equipment that will be a cornerstone of your workshop for years, so you want to make the right choice.

In a Head to Head Match, Inverter Welders Win

While you can easily find welding enthusiasts who are staunch advocates for one camp or the other when it comes to inverter welders and oil-cooled welders, at the end of the day it’s obvious that the inverter welder is the much more modern and efficient machine. In performance and ergonomic design, it is the clear winner over oil-based systems.

The oil-cooled welder does get points for higher duty cycles, durability, and historical importance, but objectively, it can’t hold its own with regards to either energy efficiency or welding precision in comparison to an inverter welder.