“This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.”

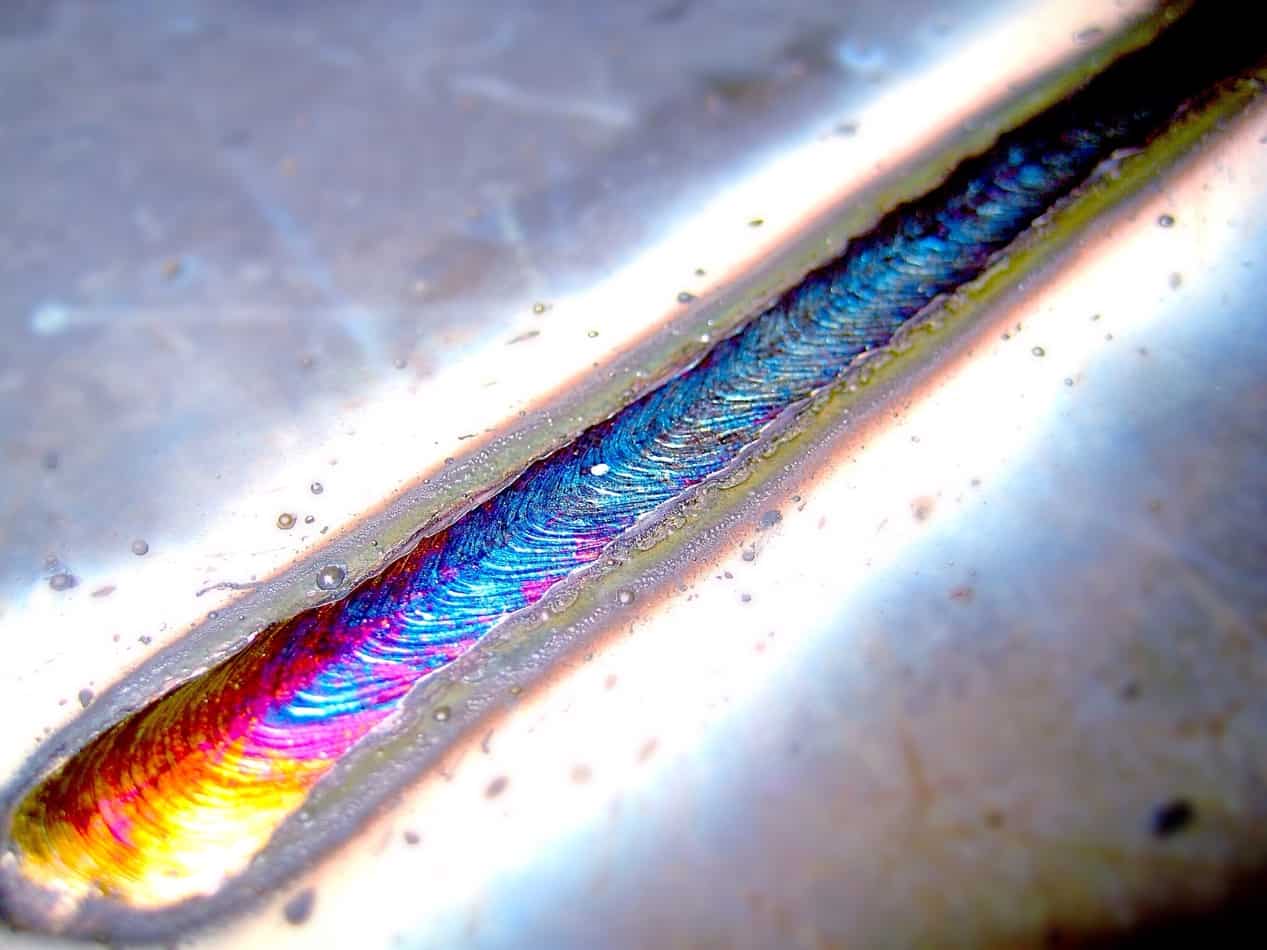

TIG welding is one of the most precise and clean welding types you can practice, but it also takes a lot of skill to learn how to do it. As you become more advanced in the craft, you will be able to not only make your welds cleaner and more specific to a desired style, but you can also impact the color. Producing a colorful TIG weld has become increasing popular for aesthetics.

How do you make a colorful TIG weld? TIG welds with a range of colors are usually made on steel. The color forms due to the contact of the weld pool of metal with oxygen. This process of oxidization and varying levels of heat applied will lead to a variety of colors in the weld. The five main factors that influence a colorful TIG weld are:

- Torch Angle

- Gas Coverage

- Heat Input

- Travel Speed

- Amperages

Let this article be your guide to creating colorful TIG welds. We will discuss the factors that allow for these colors to occur, the materials that you will be using, and all the things you should be looking for to make your TIG welds the colors you desire. There are multiple applications in which a colorful TIG weld will be desired and we’ll go over those too!

Making A Colorful TIG Weld

Colorful TIG welding has become increasingly popular in many niches of welding. Many welders on social media have gained a following with their beautiful colored TIG welding work. It can bring some really cool stylistic elements to your work or to passion projects. In this section, we will detail how colorful welds work and how you can create them.

Why Does Color Occur In TIG Welding?

TIG welding is one of the most versatile types of welding that can be used on a variety of metals. If you are looking to create a colorful weld using a TIG welder, you will often want to stick with stainless steel. You can also produce this colored effect on titanium, but there are some different considerations that need to be made as quality can be compromised.

Throughout this article, we will be referring to stainless steel application as it is the most common material you will be using to create these welds. We also don’t want to overwhelm ourselves with the chemistry of it all, but it is important to have an idea of what is the cause of the color. This will help you make you more knowledgeable about the techniques you’re using.

In TIG welding, a tungsten electrode will create an electric arc with a workpiece to create a weld. This is shielded by inert gas (often argon) to protect the workpiece from the atmosphere. With varying levels of gas coverage and heat applied, the coloration occurs when the welded metal oxidizes. This means that it has made contact with the air.

Metal of different surface temperatures will react with the oxygen differently, producing a variation in colors. The hotter temperatures will cause the metal to turn darker colors while other areas are lighter. This oxidization can cause problems related to corrosion in some cases. Mastering this skill can still produce welds that uphold their integrity.

Factors That Influence Color in TIG Welding

Now that we know that the colors produced in TIG welding are caused by oxidization, we can dive into the factors that influence the color while you are welding. The most important areas in welding that you can control for color are:

- Torch Angle: Maintaining a wider welding angle will allow more metal to be exposed in the “heat affected zone” that allows for oxidization to occur. If you keep the welder tighter to the metal (narrow and more vertical angle), less of the metal will be impacted by this heat reaction. Wider angles will lead to greater color opportunities.

- Gas Coverage: Gas coverage will be impacted by these other factors on this list. This is the area in which the inert gas shield covers along your line of welded metal. Your gas lens which can help to make a uniform coverage. If the gas coverage is left on the finished welding area as it cools, this area will remain silver or colorless. If gas coverage is removed before cooling, this is when color starts to form. This is tied to travel speed.

- Heat Input: Different levels of heat will produce different colors. Lower temperatures will result in lighter colors such as chrome (same color as metal piece), straw, and yellows. Red start to creep into higher temperatures, and blues and purples will be even higher. You know you will have reached too high of a temperature if your stainless turns a dark gray or black.

- Travel Speed: Slower travel speed will often lead to higher heat as the exposure in one area lasts longer. You don’t necessarily need to change the travel speed to produce different colors, but this will have an impact. Gas coverage and amperages work in conjunction with travel speed to produce varying levels of temperature.

- Amperages: Amperages measure the strength of an electrical current. Lower amps will require more time in an area as the strength is lower. This increased time (related to travel speed) will allow for more colors to develop as heat is increased. Amperage and travel speed can work together to produce these colors.

All of these factors work together to form color. You should make adjustments to angle and heat input to achieve desired colors. Travel speed and amperages also have an impact, but these do not have to be adjusted immediately in order to get colored welds.

Here is a chart of the higher surface temperatures that are associated with different colors you may want to achieve:

| Color | Approximate Temperature C |

| pale yellow | 290 |

| straw yellow | 340 |

| dark yellow | 370 |

| brown | 390 |

| purple brown | 420 |

| dark purple | 450 |

| blue | 540 |

| dark blue | 600 |

This table is meant to show you that there is quite a difference in color for stainless steel that is heated at different temperatures. These values should not be used in your welding as the conditions of your working environment are likely different than the ones used to form these comparisons.

Equipment and Settings Required for Colorful TIG Welds

There are some pieces of equipment you should be using or aware of when attempting to make a colorful weld. Most of these will be required for general TIG welding as well:

- TIG Welder: You will need to have a TIG welder to do this welding of course. When you set up the machine, you will want to make sure you are set to DCEN (power source and setting you will be using). You can set the pre-flow to 1 second, 10 seconds on post flow, around 85 amps, and 25 cubic feet per hour for gas. These are simple starting points that can be adjusted based on preference and your equipment. This is based on using argon gas and working with stainless steel.

- Gas Lenses: As mentioned in the section before, the gas coverage will have an impact on the color you are able to produce. Different gas lenses are the reasons for this. A larger and wider gas lens will lead to a more dramatic color appearance. This is because these lenses will diffuse the gas and make it a bit more uniform as opposed to a stronger gas coverage that focuses more drastically on the puddle.

- Foot Pedal: Because heat input is a large factor in producing different colors, you will want to use a foot pedal to dictate the amount of heat that is applied to your weld. This will give you the optimal control and should be practiced to achieve the desired heat ranges.

- Work Piece: Make sure you have a piece of metal to work with. This can vary in shape and size based on your purpose for using it.

- Filler Rod: For most color welding projects, you will want filler rod. This is a piece of metal that will be applied to fill the puddle you are working with on the workpiece. TIG welding’s use of a tungsten electrode does not use a melted metal unlike other welding types. This makes it precise, but also requires filler if needed.

- Safety Equipment: It is important to mention that safety equipment should be used in any type of welding. This includes a quality functioning helmet, welding gloves, protective clothing that covers your skin, and closed-toed shoes. Make sure you are not damp when working with welders as this may lead to electrical accidents.

Having this equipment will ensure you are working in an environment that is conducive to proper welds with all the necessary tools.

The technique for Colorful TIG Welds

You have all the information that impacts the color of a weld. Now let’s put that into practice. When trying to achieve a colorful weld, there are different techniques to go about the process. Here is a step-by-step guide you can follow to make a colorful TIG weld:

- Set your machine: These settings will vary based on your equipment and preferences. The key is that you want your welding machine to be set up with a foot pedal so that you can adjust the heat input to be applied to the weld.

- Heat Setting: Apply your foot to the pedal to give an intense amount of heat and move more quickly. If you set it to a low setting, you will have to stay there longer and this could cause the metal to fry and turn gray (try increasing amperage and increasing travel speed). You will want to give intense heat to form a puddle, then melt the rod, and take off some heat (less pedal). You can keep moving with this process until you get the hang of it.

- Thickness: Metal thickness will also impact the color as it impacts temperature. Thinner metal is harder to work with and will overheat more quickly. This could lead to quick gray or black stainless steel if you are not experienced. Start with thicker pieces of metal that can absorb heat more easily.

- Keep Tungsten near puddle: You should try and keep the electrode as close to the puddle as possible. This will allow for quicker melting and welding work without overheating the piece.

You can practice without a filler rod first on a piece of metal to work on achieving your desired colors. You will want to note the settings you used and how your work measured up to the many factors that influence color. You should make adjustments as necessary.

Colorful TIG Welds in Practice

Colorful TIG welding is often not just used as a hobby to practice your technique but is used in the real world. Different industries have different requirements for colors as they can impact the integrity of the weld.

Colorful TIG Weld Applications

There are different applications for TIG welding with a wide color spectrum. Colorful TIG welding is becoming more popular today as an art form in addition to practical welding applications.

- Art: Many welders are using their TIG skills to make rainbow-colored metal art. These artists have gained strong social media followings showing off their skills and sell their work with many designs and styles. Metal sculptors may make use of this technique as well.

- Automotive: Welders may use colored welds on cars and motorcycles for aesthetic purposes. They are not being used to hold important pieces of metal together, but are used to enhance the dramatic colors associated with the practice.

The colors that are accepted for TIG welding will depend on the industry you are working in. For welding jobs that require strong integrity and durability, darker colors such as blues and purples will likely not be accepted, especially because they suggest greater corrosion likelihood. Your lighter yellows and golds should be accepted. This is very job and industry-specific.

Most people who are looking to make colorful welds are doing so for presentation reasons rather than strength. Chrome and very light gold welds are preferred in creating a “successful” weld that will be long-lasting.

Risks Associated with Colorful TIG Welds

When attempting to make a colorful TIG weld, there are some drawbacks that could impact your welding quality. These include:

- Too much heat: In wanting to achieve darker blues and purples, you could end up applying too much heat and scorching your stainless steel. This could lead to grays, blacks, and worst case: burning right through the workpiece. You will need to play around with the heat and try going with less at first.

- Corrosion: Darker colors mean more oxide. This is less corrosion resistance, which may put the strength of the weld into question. If corrosion would be detrimental to the work you are doing, you should not try to achieve these darker colors in your weld.

- Material: If you are using another material, such as titanium, you can still achieve colorful TIG welds. You should know the properties of the metals you are using as colorful welds can have very different outcomes. Exposure to the environment for titanium can actually pull in other elements that impact the weld quality. This may lead to brittle welds that become ineffective.

If you are looking to make a very sturdy weld, colorful TIG welds are not going to be the best option. Some of these risks could result in damage or allow the weld to fail. Colorful welding should be reserved for situations related to aesthetics, where the durability of the weld does not have to be the largest concern.

Making A Colorful TIG Weld

Colorful TIG welding has become a popular art form because the combination of stainless steel and the electrode-based welder produces some incredibly striking colors. With the ability to create amazing designs in a metal rainbow style, many welders want to learn how they can do it themselves. Using a TIG welder also makes these designs much more precise and accurate.

When using a TIG welder to make colorful welds, you should be mindful of the equipment you are using and the techniques you apply to achieve the best results. Many of these techniques are different from welder to welder.

The key is to make sure you are using a foot pedal to control heat input, and are controlling the gas coverage, amperage, travel speed, and torch angle to achieve different colors. Greater temperature of the oxidized metal will lead to darker colors, while cooler temperatures produce the lighter chromes, straws, and golds that are often desired in most welding work.

With lots of designs and interesting projects to work on while making colorful welds, learning how to manipulate color will not only allow you to create interesting projects, but it will also help you to gain a better understanding and technique for choosing when to use color. Mastering colorful welding can help you to prevent it when you work on other jobs.

For further reading, apart from my posts obviously, I recommend this book. A great resource to advance your TIG skills.